Material:polyurethane acrylic + quartz sand

Advantages:

Fast cure, high construction efficiency

Suitable for various anchorage fasteners, small spacing/edge distance

Excellent property of load-bearing, anti-seismic and anti-welding

Wide working temperature range, even -10℃

No phenylethene, non-toxic

Applications:

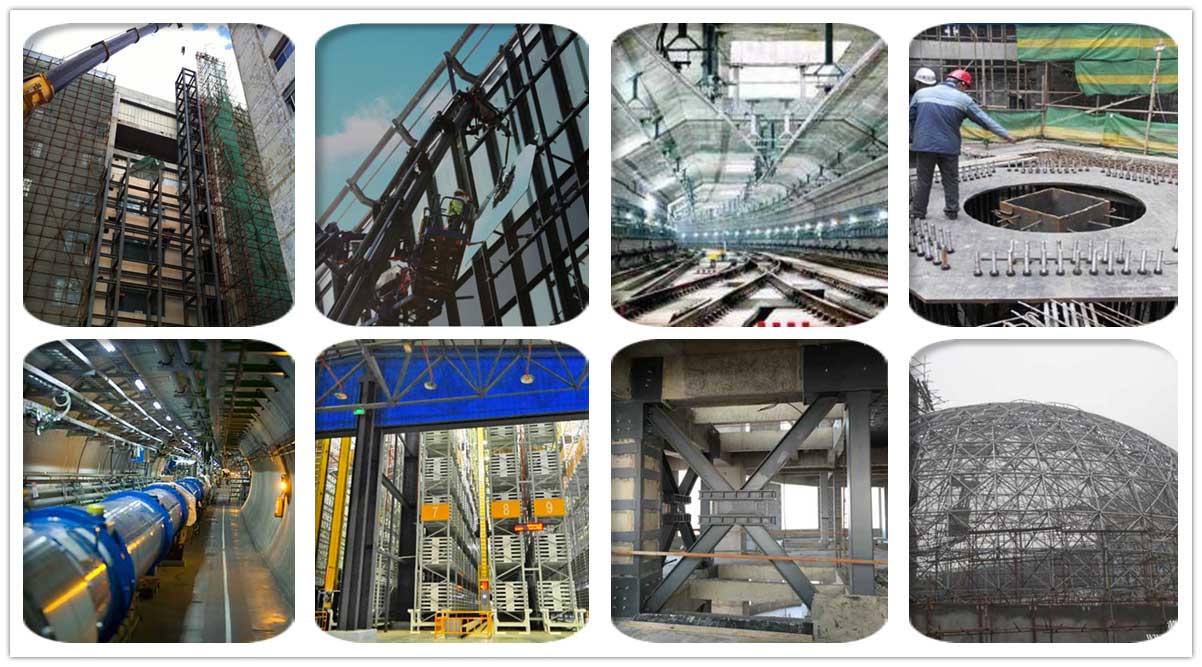

Curtain wall

Steelwork constructions

Equipment fixing

Pipeline, bracket

Baffle plate, hanging plate, acoustical plate

Installation:

Drill the hole to proper depth and diameter per specifications using ordinary impact drill; the verticality, hole diameter of embedded plate, maximum spacings, etc. are in accordance with JGJ/145-2013.

Blow the hole clean using compressed air.

Put the resin capsule into the drilled hole.

Before installation, firstly break the glass tube with the anchor, then use the setting tool to drive the anchor into the drilled hole until the mark of the anchor is tight against the surface of concrete base material.

After the cure, place the fixture.

Storage:

Please store in dry and well-ventilated place, away from open flame, heating devices, dust, rain, light and UV.

Match NJMKT Adhesive Anchor

A. Installation data and force value----8.8 uncracked concrete

| ype | Length | Effective embedment depth | Tensile standard/ design value | Shear standard/ design value | Drill bit dia. | Max. fixture thickness | Installation torque | Influence coefficient k for hef to Vrd, cp | Concrete cone failure | Recommended tensile/shear | Concrete splitting failure | ||||

| critical edge distance | critical spacing | Min. spacing | Min. edge distance | Critical spacing | Critical edge distance | ||||||||||

| M8 | 110 | 80 | 29.3/19.5 | 11.7/9.3 | 10 | 16 | 12 | 2.0 | 120 | 240 | 8.7/4.0 | 48 | 48 | 240 | 120 |

| M10 | 130 | 90 | 41.8/23.2 | 18.5/15.5 | 12 | 22 | 20 | 2.0 | 135 | 270 | 16.8/11.1 | 60 | 60 | 270 | 135 |

| M12 | 160 | 110 | 56.5/31.4 | 26.9/22.5 | 14 | 24.5 | 40 | 2.0 | 165 | 330 | 22.4/16.0 | 72 | 72 | 330 | 165 |

| M16 | 190 | 125 | 68.5/38.0 | 50.2/41.8 | 18 | 31 | 60 | 2.0 | 190 | 375 | 27.1/29.8 | 96 | 96 | 375 | 190 |

| M20 | 260 | 170 | 108.6/60.3 | 78.4/65.3 | 25 | 57.5 | 100 | 2.0 | 255 | 510 | 43.0/46.6 | 120 | 120 | 510 | 255 |

| M24 | 300 | 210 | 149.1/82.8 | 112.9/94.1 | 28 | 53 | 160 | 2.0 | 315 | 630 | 59.1/67.2 | 144 | 144 | 630 | 315 |

| M27 | 350 | 250 | 193.6/107.5 | 146.8/122.4 | 32 | 63 | 200 | 2.0 | 375 | 750 | 76.8/102.0 | 160 | 160 | 750 | 375 |

| M30 | 380 | 280 | 229.5/127.5 | 179.5/149.6 | 35 | 59 | 240 | 2.0 | 420 | 840 | 91.1/106.9 | 180 | 180 | 840 | 420 |

B. Installation data and force value----8.8 cracked concrete

| Type | Length | Effective embedment depth | Tensile standard/ design value | Shear standard/ design value | Drill bit dia. | Max. fixture thickness | Installation torque | Influence coefficient k for hef to Vrd, cp | Concrete cone failure | Recommended tensile/shear | Concrete splitting failure | ||||

| critical edge distance | critical spacing | Min. spacing | Min. edge distance | Critical spacing | Critical edge distance | ||||||||||

| M8 | 110 | 80 | 25.1/13.9 | 11.7/9.3 | 10 | 16 | 12 | 2.0 | 120 | 240 | 9.9/6.6 | 48 | 48 | 240 | 120 |

| M10 | 130 | 90 | 29.8/19.4 | 18.5/15.5 | 12 | 22 | 20 | 2.0 | 135 | 270 | 13.8/11.1 | 60 | 60 | 270 | 135 |

| M12 | 160 | 110 | 40.4/22.4 | 26.9/22.5 | 14 | 24.5 | 40 | 2.0 | 165 | 330 | 16.0/16.0 | 72 | 72 | 330 | 165 |

| M16 | 190 | 125 | 48.9/27.2 | 50.2/41.8 | 18 | 31 | 60 | 2.0 | 190 | 375 | 19.4/29.8 | 96 | 96 | 375 | 190 |

| M20 | 260 | 170 | 77.5/43.1 | 78.4/65.3 | 25 | 57.5 | 100 | 2.0 | 255 | 510 | 30.8/46.6 | 120 | 120 | 510 | 255 |

| M24 | 300 | 210 | 106.5/59.1 | 112.9/94.1 | 28 | 53 | 160 | 2.0 | 315 | 630 | 42.2/67.2 | 144 | 144 | 630 | 315 |

| M27 | 350 | 250 | 138.3/76.8 | 146.8/122.4 | 32 | 63 | 200 | 2.0 | 375 | 750 | 54.8/102.0 | 160 | 160 | 750 | 375 |

| M30 | 380 | 280 | 163.9/91.1 | ||||||||||||