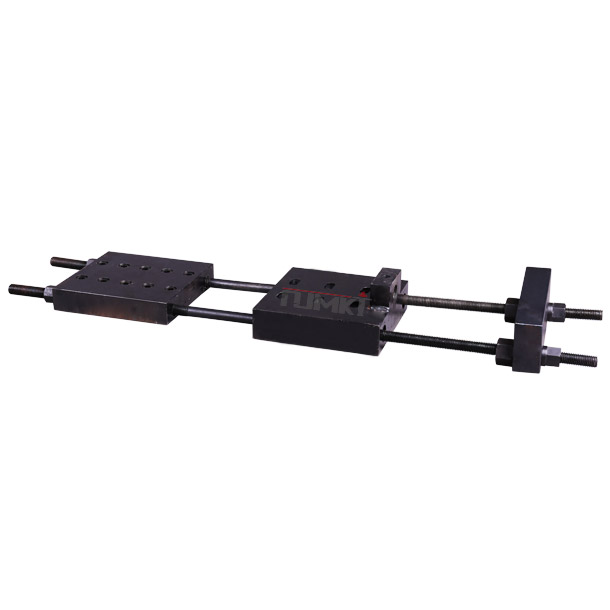

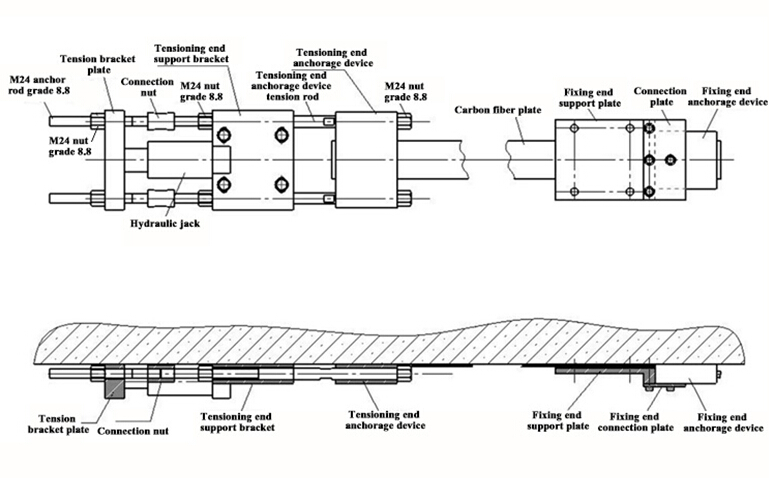

NJMKT carbon fiber plate prestressed anchorage device adopts specialized steel, modified treatment quenching and tempering, when stretching adopts manual hydraulic jack device for tension, simple operation, matched with our production of special prestressed carbon fiber plate, special adhesive and other attachments that consist of of prestressed carbon fiber plate reinforcement system. The working principle of the system is similar to external prestressed steel strand reinforcement system. It is a kind of reinforcement method that the system is prestressed to the system through jack device to apply pretension, so that the system keeps a stable state of tension condition in the external of structural components, contribute to pre-stress unto original structure components.

Consist:

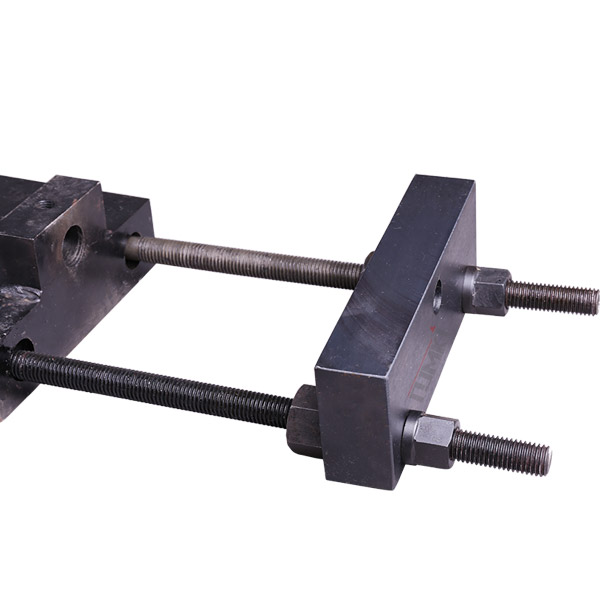

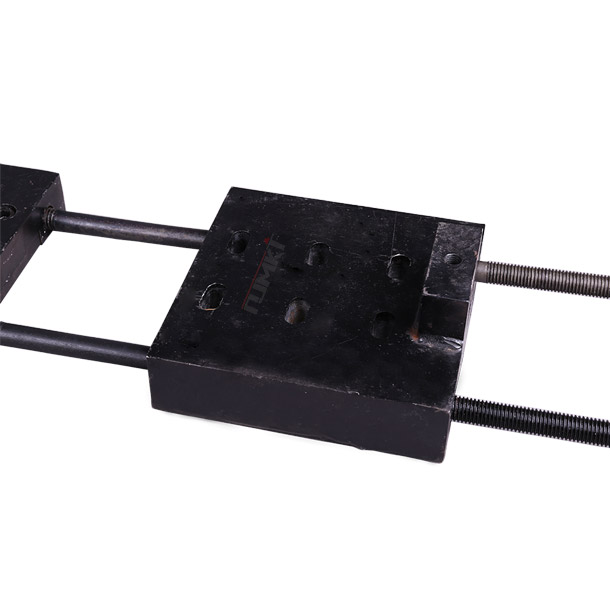

M24 anchor rod grade 8.8/ M24 nut grade 8.8/Tension bracket plate/Connection nut/M24 nut grade 8.8/Tensioning end support bracket/Tensioning end anchorage device tension rod/Tensioning end anchorage device/M24 nut grade 8.8/Carbon fiber plate/Fixing end support plate/Connection plate/ Fixing end anchorage device

Hydraulic jack

Tension bracket plate/Connection nut/Tensioning end support bracket/Tensioning end anchorage device/Fixing end support plate/Fixing end connection plate/Fixing end anchorage device

Advantages

● The design of our prestressed carbon fiber plate reinforcement system is based on the principle of early stage prestressed steel strand reinforcement system, optimized and developed according to Design Code for Strengthening Highway Bridges JTG/TJ22-2008 and Design Code for Strengthening Concrete Structure GB50367-2013 for reference, so our system is scientific and practical, and it has advantages of beautiful appearance and convenient installation, etc.

● NJMKT prestressed carbon fiber plate anchorage device has obvious advantages than ordinary anchorage, especially in materials: ordinary anchorage device is cast steel element, without modified treatment quenching and tempering, the elastic modulus of cast element itself is high, and great brittleness. When stretching in use of electric automatic pressure electric device, resulting in high risk, the safety of anchorage can not be guaranteed. But NJMKT prestressed carbon fiber plate anchorage reinforcement device manufactured in our factory adopts specialized steel with modified treatment quenching and tempering, and use hand-actuated hydraulic device to simulate the tension control, thus high performance of safety and flexible operation.

● It has been widely applied in pre-tension or post-tension for bridge, railway and highway construction, etc.

● Bending / tension / large eccentric compression members reinforcement, for steel concrete of small cross-section, inadequate arrangement of reinforcement

● Reinforce long-span beam, plate bending reinforcement, improve bearing capacity of the structure, reduce crack width and deflection deformation

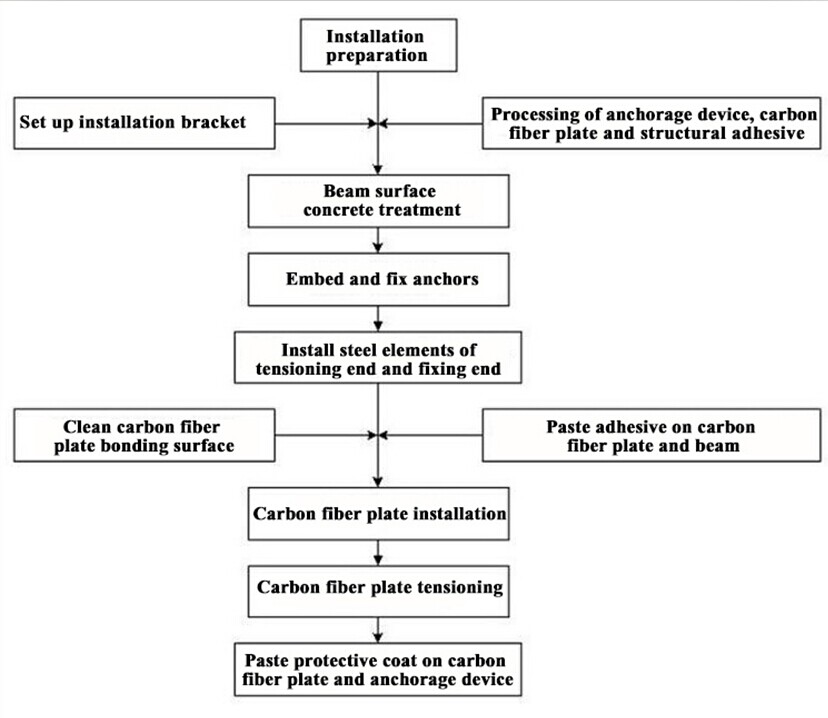

Installation Guide:

1.Preparation in advance

2.Anchors installation

3.Make anchorage device

4.Apply repairing adhesive

5.Apply bonding adhesive

6.Anchorage device installation

7.Anchorage device tensioning

8.Post-processing treatment

Installation preparation

Set up installation bracket Processing of anchorage device, carbon fiber plate and structural adhesive

Beam surface concrete treatment

Embed and fix anchors

Install steel elements of tensioning end and fixing end

Clean carbon fiber plate bonding surface Paste adhesive on carbon fiber plate and beam

Carbon fiber plate installation

Carbon fiber plate tensioning

Paste protective coat on carbon fiber plate and anchorage device

| Size and specifications | Shear mounting adhesive anchor | Anchorage embedment depth | Anchorage clamping force ( plate max. sliding tension) | Carbon fiber plate min. spacing | Hydraulic jack model | |||

| NJMKT - MJ 50 | (M12 - M20) * 4 | 170 | ≥ 150kN | 250mm | RC20-100 | |||

| NJMKT - MJ 100 | (M12 - M20) * 8 | 170 | ≥ 280kN | 250mm | RC30-150 | |||

| Equipment Tools | ||||||||

| No. | Name | Quantity | Note | |||||

| 1 | Tension bracket | 1 set | ||||||

| 2 | Thrust bracket | 1 set | ||||||

| 3 | Carbon fiber mounting plate | according to actual need | ||||||

| 4 | Steel detector | 1 set | ||||||

| 5 | Infrared detector | 1 set | ||||||

| 6 | Diamond grinding wheel | according to actual need | ||||||

| 7 | Center-hole oil-pressure jack (30T stroke 150mm) | 1 set | ||||||

| 8 | Electric hammer, ink marker, tape measure, wrench | 1 set | ||||||

| 9 | Electric grinding machine | 1 set | ||||||

| 10 | Coarse sand sheet | according to actual need | ||||||

| 11 | Absolute alcohol | according to actual need | ||||||

| Equipment Materials | ||||||||

| 1 | Anchorage device | 1 set | Tensioning end, fixing end | |||||

| 2 | Carbon fiber plate | 1 piece | Length--according to actual need | |||||

| 3 | Special structural adhesive for prestressed carbon fiber plate | according to actual need | Bond carbon fiber plate | |||||

| 4 | Epoxy mortar | according to actual need | Anchorage device and plate protection sealing | |||||

| 5 | Epoxy repair adhesive | according to actual need | Side beam anchorage installation repair | |||||

| 6 | Epoxy fast-cure structural adhesive | according to actual need | Anchorage mounting clamping plate fast-cure bonding | |||||

| 7 | M18 adhesive anchor ( grade 8.8) | 8 sets (May vary depending on design) | Tension bracket, fixing end | |||||

| 8 | M12 adhesive anchor ( grade 8.8) | 12 sets (May vary depending on design) | Anchorage lock | |||||