Key Features

● Consist: high strength anchor rod, spacer sleeve, Z-type pressure ring, spring washer, nut

● Material: A4 stainless steel, higher ultimate load capacity than ordinary standard, and high corrosion resistance steel A4-70 (316L) can be applied in harsh environment, such as, splashing seawater environment, swimming pools with chlorine, industrial environment with SO2, etc.

Advantages

● Displacement control undercut anchor, convenient and quick installation

● Installation process is easy to control, wide construction coverage

● Lock-effect anchor fixing, initial installation stress is nearly negligible, low installation stress ensures the protection of panel materials

● Closed Z-type ring structure has completely dispersed temperature stress caused by different temperature strain between the stone and anchor, which is the problem of ordinary panel anchor application

● Immediate load-carrying capability as soon as it is installed

The design of internal thread can effectively prevent the pressure ring loose off, increased the safety factor

● The check washer and check nut ensure the connection of curtain wall and keep the security and stability in the long-term wind load

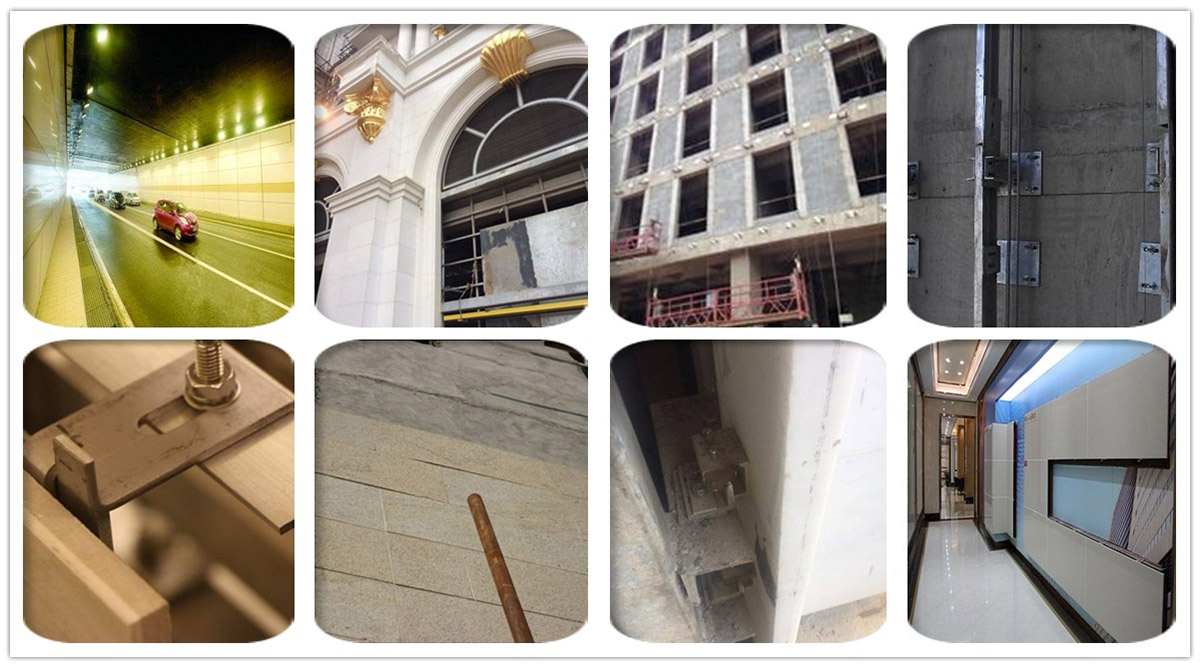

suitable for fixing plate of buildings outside maintenance construction, especially natural stone decoration plate, and also ceramic plate, marble plate, granite, microcrystalline stone, crystal glass, man-made fiber board, etc.

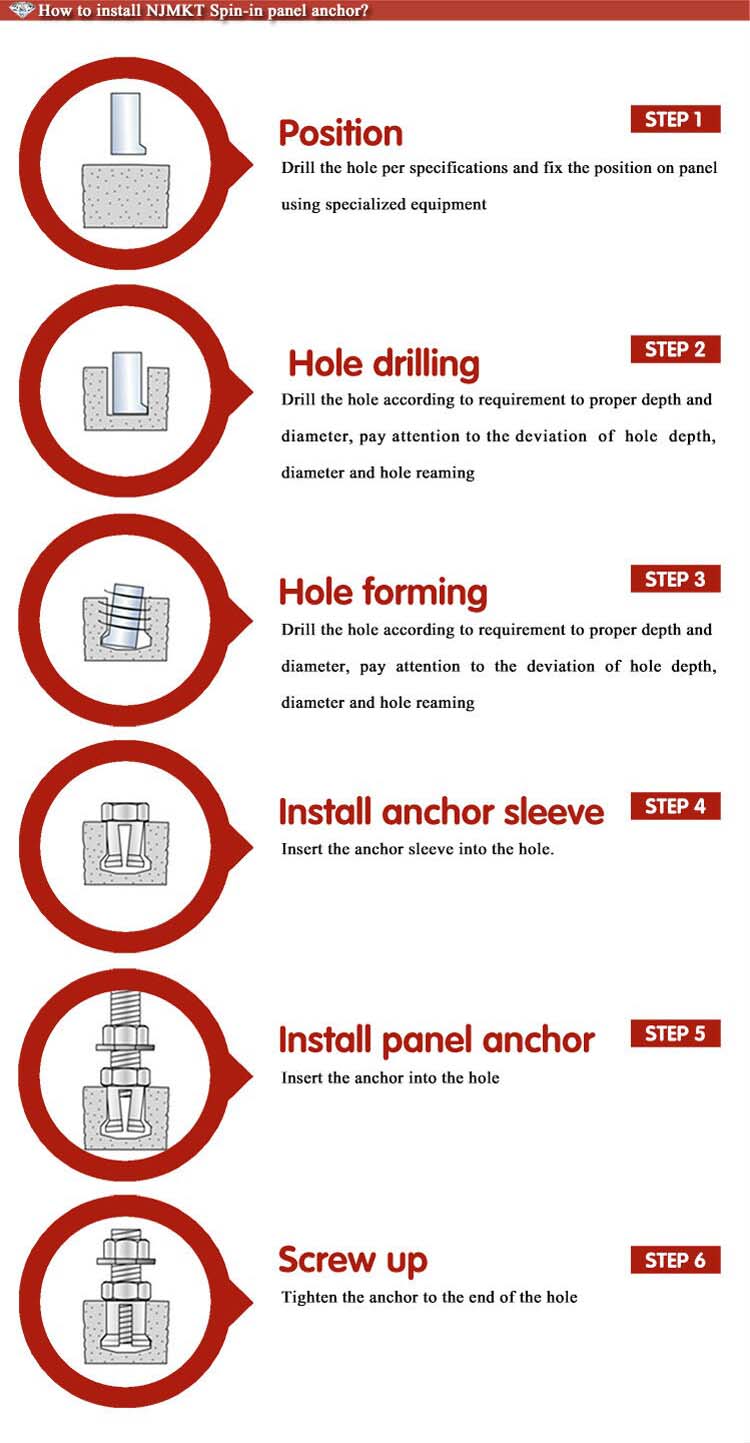

Installation Guide (spin-in undercut panel anchor)

Step 1 Position: Drill the hole per specifications and fix the position on panel using specialized equipment.

Step 2 Hole drilling: Drill the hole according to requirement to proper depth and diameter, pay attention to the deviation of hole depth, diameter and hole reaming.

Step 3 Hole forming: Drill the hole according to requirement to proper depth and diameter, pay attention to the deviation of hole depth, diameter and hole reaming.

Step 4 Install anchor sleeve: Insert the anchor sleeve into the hole.

Step 5 Install panel anchor: Insert the anchor into the hole.

Step 6 Screw up: Tighten the anchor to the end of the hole.

| Size | Drilled hole dia.[mm] | anchorage depth [mm] | Enlarged hole dia.[mm] | rod dia.[mm] | Outside length of rod [mm] |

| M6 × 5 × 20 | 11 | 5 | 13.5 | M6 | 15 |

| M6 × 7 × 20 | 11 | 7 | 13.5 | M6 | 13 |

| M6 × 10 × 25 | 11 | 10 | 13.5 | M6 | 15 |

| M6 × 12 × 25 | 11 | 12 | 13.5 | M6 | 13 |

| M6 × 15 × 32 | 11 | 15 | 13.5 | M6 | 17 |

| M6 × 18 × 32 | 11 | 18 | 13.5 | M6 | 14 |

| M6 × 21 × 32 | 11 | 21 | 13.5 | M6 | 11 |

| M8 × 15 × 32 | 13 | 15 | 15.5 | M8 | 17 |

| M8 × 18 × 35 | 13 | 18 | 15.5 | M8 | 17 |

| M8 × 21 × 35 | 13 | 21 | 15.5 | M8 | 14 |

| M8 × 25 × 40 | 13 | 25 | 15.5 | M8 | 15 |

| M8 × 30 × 45 | 13 | 30 | 15.5 | M8 | 15 |

| M8 × 35 × 50 | 13 | 35 | 15.5 | M8 | 15 |

| M8 × 40 × 55 | 13 | 40 | 15.5 | M8 | 15 |

1. A4 stainless steel, higher ultimate load capacity than ordinary standard

2. Small installation stress ensures the protection of panel materials

3. The design of internal thread can effectively prevent the pressure ring loose off, increased the safety factor

4. The check washer and check nut ensure the connection of curtain wall and keep the security and stability in the long-term wind load