Carbon fiber sheet is fibrous carbon material. It is a new material, with stronger strength than steel, lower density than aluminum, greater corrosion-resistance and high-temperature resistance than stainless steel and heat resistance steel respectively, and the capability of conducting electricity as the same as cooper.Besides, it abounds in many valuable electric, thermal and mechanical properties. So that the carbon fiber sheet are widely used in architectural reinforcement.

1.The restoration of tension components

Using affixing carbon fiber sheet as reinforcement has better effect in increasing the loading ability of tension components in steel structure. Using carbon fiber reinforcement lengthways, the debonding failure will happen between carbon fiber sheet and steel structure. While adopting circular carbon fiber reinforcement, it won’t cause debonding failure and the sheet won;t break neither, as a result, partial buckling failure will also not happen to the steel column. The tensile test of single shaft conducted on carbon fiber reinforced steel plate shows that the yield strength and ultimate load of test piece are improved significantly, and as sticking area increase, its yielding load will increase accordingly.

2.The restoration of bending member

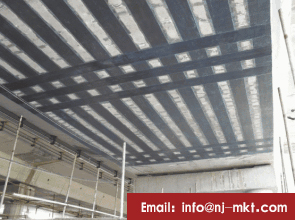

To restore the bending member of steel structure,carbon fiber sheet is usually pasted on the bottom of tensile flange. When the bending member is stressed, the carbon fiber will bear load together with tensile flange,increasing the load capacity of the beam. After adopting carbon fiber reinforcement,the flexural capacity of beam will be increased, increased degree relates to the amount of fibers inside the stickup, elasticity modulus of fiber and steel, the yielding strength of steel and so on. Though carbon fiber strength is high, its elasticity modulus is close to steels. When the load on integral steel structure reaches the amount of its yielding load, carbon fiber material’s strength only can reach about 200MPa, far from its available strength and its high strength can not give full play to steel reinforcement.

As for damaged steel beam, the restoration of affixing carbon fiber reinforcement not only can restore its damaged rigidity, load capacity and improve its fatigue performance, but also form protection on steel structure, gaining the ability of reinforcement and corrosion resistance. When carbon fiber is pasted, it should be pasted to the surface of the damaged area, conveying a part of load capacity through bond line to carbon fiber, which can decrease the nominal stress of damaged area of steel structure, and decrease crack growth rate or stop crack’s extension, as a result, the lifetime of steel structure can be extended.

3.prestressed carbon fiber reinforcement

Due to the elasticity modulus of prestressed carbon fiber is close to steels,when usual surface pasting method in steel structure reinforcement is adopted, under normal operating condition, its strength can not be utilized fully, and reinforcement makes no significant effect in improving its property. While if adding prestress to the carbon fiber sheet, then pasting it on the tension area for reinforcement, all problems listed above can be solved. In addition, using prestressed anchorage device to paste reinforcement on both edges of the carbon fiber sheet, which can avoid the earlier debonding failure happening between the carbon fiber sheet and the steel girder. Therefore, the prestressed carbon fiber sheet has a promising future in steel structure reinforcement.

4.The restoration of steel pipeline suffered internal pressure

Because the steel pipeline often suffers high temperature, under high pressure, plus with inflammable, explosive, toxic,corrosive media inside it, if leakage and explosion happen to the pipeline, horrible results will follow. Therefore, there is practical significance to ensure the safety of pipeline. After using carbon fiber reinforcement, under internal pressure, the shell of pipe majorly suffer circumferential stress. Then the pipeline will swell, and radial deformation will be constrained by the external wrapped carbon fiber, enabling carbon fiber and pipeline suffer the strength together, which will reduce circumferential stress and increase its bearing capacity toward internal pressure.

5.The restoration of steel structure’s fatigue damages

The main feature of fatigue damage is the damage happens when failure stress is lower than static stress-strength, and is one dominant failure mode that after suffering repeating load, the construction structure will lose its efficacy. After using carbon fiber reinforcement on components, under alternating load, its load capacity will be increased, stress amplitude decreased, indirectly extending its fatigue strength and lifetime. For welding structure components, carbon fiber relieve a part of stress upon weld toe, decreasing the concentration factor of stress upon weld toe and improving its fatigue performance.

Carbon fiber sheet manufactured by Nanjing Mankate has passed the ISO Quality System Standards and EU CE Certification. It is the brand broadcasted on CCTV, whose products safety is approved under national high requirements and covered Ping An Insurance Company of China. NJMKT carbon fiber sheet adopts first-class carbon fiber filament whose strength reaches to 3800MPa. It abounds in great braiding technology, high flatness, easy adhesive impregnating, less labour and money. There are few industries owning the same testing equipment as national inspection center, which allow customers to inspect its tensile strength, elasticity modulus and elongation on the spot, and place orders after seeing its data!

Editor: NJMKT

The copyright is reserved by www.nj-mkt.com. If reprint please indicate its source.