"I heard that unidirectional carbon fiber cloth is very suitable for house reinforcement. Is this true? I want to know how unidirectional carbon fiber cloth is used in house reinforcement. What is the specific construction process, can you give me brief explanation to it? "A few days ago, we received an inquiry from the colleagues in the reinforcement industry, so we quickly answered the friend about the characteristics of unidirectional carbon fiber cloth and the specific construction process.

Unidirectional carbon fiber cloth is a new type of building reinforcement material. It is as small as cloth and very thin. However, it has high compressive strength and high elastic modulus. Construction using unidirectional carbon fiber cloth does not increase the weight of the component. It also does not change the section size of the component, and has the advantages of high plasticity, convenient construction and wide construction range. There is nothing wrong with using unidirectional carbon fiber cloth to strengthen the house.

Mankate unidirectional carbon fiber cloth is lightweight and high-strength, which is a good assistant for engineering ~

So how should unidirectional carbon fiber cloth be used? We will use Mankate Unidirectional Carbon Fiber Cloth and Mankate Carbon Fiber Glue as examples to briefly explain to everyone.

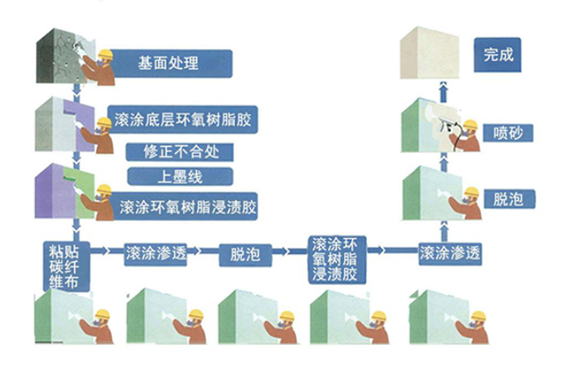

First of all, we need to treat the base surface and use tools to fully polish the base surface of the building to ensure that there is no attachment on the base surface. Then, the carbon fiber screed is applied to the surface of the substrate by roller coating to correct the inconsistencies, and the ink line is used to facilitate later engineering construction.

Mankate carbon cloth carbon adhesive constitutes a carbon fiber system, allowing the building to live for more than 50 years ~

Next, the carbon fiber dipping glue is applied to the bonding surface by roller coating. Note that the amount of glue must be sufficient, otherwise the effect of reinforcement will be reduced. Then cut the unidirectional carbon fiber cloth to the glued surface of the concrete, and the unidirectional carbon fiber cloth should be straight and stretched.

The next step is to fully apply the carbon fiber impregnated adhesive on the unidirectional carbon fiber cloth. The amount of glue must be guaranteed to cover the surface of the unidirectional carbon fiber cloth, otherwise the fibers in the unidirectional carbon fiber cloth will not be fully wetted. The squeegee is repeatedly rolled to make the unidirectional carbon fiber cloth appear flat, stretched, air-free and fully penetrated by the carbon fiber glue. At this time, the construction process of unidirectional carbon fiber cloth has been more than half completed.

The remaining step is to roll on the carbon fiber impregnated adhesive to penetrate the unidirectional carbon fiber cloth and repeatedly scrape and defoam using a doctor blade. Then spray 3-6mm sand and gravel on the construction surface coated with glue to ensure the adhesion of the paint layer.

The correct construction process of Unidirectional carbon fiber cloth reinforcement, you can check it out.

After reading the explanation above, do you have a deeper understanding of the characteristics of unidirectional carbon fiber cloth and the construction process? If you, like the friend above, don't know the construction process of unidirectional carbon fiber cloth, please call Mankate’s one-stop hotline: 400-894-5118.

Link to this article: https://www.njmkt.net/Article/txwbrhyyzf.html

(Editor: Nanjing Mankate, if you need to reprint, please indicate the source)