If the building is used for a long time, it will encounter some quality problems over time, and it may also change the building function, which leads to the need to modify the structure. In either case, the structure of the building needs to be specifically reinforced. The load-bearing structure of the building is generally the beam and the column, and in the transformation, the reinforcement is mainly for the beam and the column.

There are two methods for the reinforcement of beams and columns of a building. One is to add a cross-sectional area to the original foundation to achieve a way to increase the load. The other is to add other reinforcement materials to the original components to achieve the principle of common force and increase the load.

Today, I mainly talk about how to add other reinforcing materials to the original components. The commonly used beam and column reinforcement methods are unidirectional carbon fiber cloth reinforcement. The principle of unidirectional carbon fiber cloth reinforcement is to use high-performance carbon fiber matching resin impregnating glue to bond to the surface of the concrete member and utilize the outstanding tensile strength of the carbon fiber material to achieve the purpose of enhancing the bearing capacity and strength of the member.

1. Unloading: Before the reinforcement, first reduce the other load on the reinforcing member to ensure its original state, and the surface has no interference.

2. Substrate treatment: remove the inferior layer of the surface which has fallen off, broken, moldy and so on. After the chiseling, the epoxy leveling glue MKT-LG is used for repair. If the surface is uneven, use a concrete corner machine to polish the protrusions and keep them dry.

3. Apply the primer: according to the Mankate instructions, mix with a power agitator, and evenly apply the primer to the surface of the component with a roller brush. After the gel is solidified, proceed to the next step.

4. Paste unidirectional carbon fiber cloth: Cut the unidirectional carbon fiber cloth according to the size and number of layers required by the design. Unless special requirements, the length of the fiber cloth should generally be within 3m. Mix and stir the dipping glue (the method is the same as the bottom glue), then apply it evenly to the part to be pasted, paste the unidirectional carbon fiber cloth, roll repeatedly along the fiber direction with the roller, remove the air bubbles, and make the glue fully penetrate the fiber cloth. The above steps should be repeated for multi-layer bonding. After the surface of the fiber cloth is dry, the next layer can be pasted. Apply a face coat evenly on the surface of the last layer of unidirectional carbon fiber cloth. The overlap length of the fiber cloth along the fiber direction shall not be less than 100 mm, and the end of the fiber cloth shall be fixed by a transverse fiber cloth or a steel.

5. Maintenance: Apply the plaster or fireproof material to the surface after the paste is finished for protection.

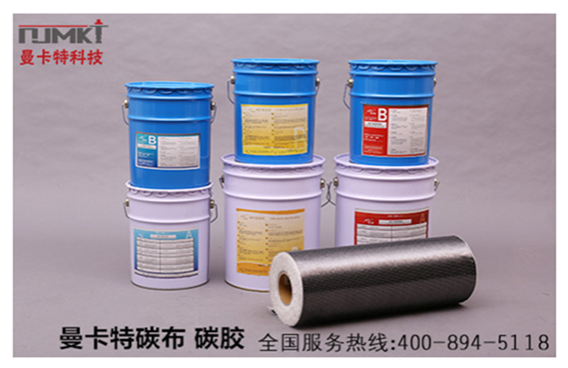

Mankate unidirectional carbon fiber cloth and carbon fiber glue

Building reinforcement must be targeted. If the reinforcement method is used correctly, it will be more effective. The unidirectional carbon fiber cloth reinforcement can effectively enhance the load capacity of the beam and column. It does not increase its own weight. It is an excellent beam reinforcement material. Please call Nanjing Mankate: 400-894-5118

Link to this article: https://www.njmkt.net/

(Editor: Nanjing Mankate, if you need to reprint, please indicate the source)