If you have read our previous articles before, you will find that we have introduced a lot of structural reinforcement methods. The effect of structural reinforcement plays a key role in the stability and safety of buildings, so we think It is time to give you a summary.

1. The method of increasing the section

The method of increasing the section is to increase the cross-sectional area of the component (concrete and reinforcing amount) to achieve a traditional reinforcement method to improve the bearing capacity of the component. The advantage of this reinforcement method is that the process is simple, the technology is mature, the reliability is strong, and the rigidity and stability of the component can be improved. The shortcoming is that the on-site wet work is heavy and the maintenance time is long, which will have certain impact on production and life, and will have certain influence on the shape of the original structure and the space for the house.

2, The method of outsourcing steel reinforcement

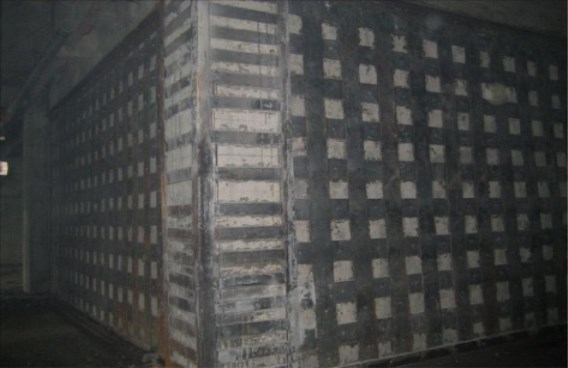

The method of outsourcing steel reinforcement is a reinforcement method for the steel beam (usually angle steel, flat steel or steel plate) in the 4 corners or 2 sides of concrete, masonry and other components, and is also a widely used traditional method. The utility model has the advantages of simple construction, small on-site workload and relatively reliable force, and is suitable for reinforcement of columns, beams, truss chords and webs, and high-rise buildings. The disadvantage of this method is that the amount of steel used is large, the reinforcement and maintenance cost is high, and the structural rigidity is not improved much.

(Outsourcing steel reinforcement effect)

3, The method of additional prestressing reinforcement

The method of prestressing reinforcement is reinforcing structural members or the whole by using pre-stressed tensile anchors and carbon fiber sheets. It indirectly improves the bearing capacity of the structure by changing the internal force distribution of the original structure and reducing the original stress level of the structure. The prestressed reinforcement method hardly changes the use space, and eliminates the stress hysteresis by the unloading and reinforcement functions to achieve an ideal reinforcement effect.

(Prestressed carbon fiber board reinforcement effect)

4. The method of bonded steel reinforcement

The method of bonded steel reinforcement is attaching the structural adhesive of the steel plate to the outside of the concrete member to improve the bearing capacity of the structure. This corresponds to the in vitro reinforcement of the component. The technology is now maturing. The advantage is that the shape and the use space of the component are hardly changed. The construction is simple, fast, and the wet work is little. However, there is a requirement for the working environment of the reinforcing member. The ambient temperature is not higher than 60 ° C. The relative humidity is not more than 70%, and there is no chemical corrosion. Otherwise, corresponding measures should be taken. It is suitable for the reinforcement of bent and tensioned members subjected to static action and under normal environment. It is currently widely used in bridges and housing structures.

(Bonded steel reinforcement effect)

The method of pasting fiber composite

The method of reinforcing the fiber composite material is similar to the steel reinforcement method, except that the reinforcement material is a fiber composite material such as glass fiber (GFRP), carbon fiber (CFRP), aramid fiber (AFRP) and the like. It is a reinforcement method with many researches at home and abroad and great development potential. Compared with traditional reinforcement materials, fiber composites have outstanding advantages such as high strength, light weight, convenient construction and corrosion resistance. As far as carbon fiber is concerned, its tensile strength is about 3,000 MPa, which is 10 times higher than ordinary steel bars. Its elastic modulus is slightly higher than that of steel bars, and it has been used for reinforcement of various structures such as beams, slabs, columns, bridges and roof trusses.

(The effects of carbon fiber cloth reinforcing the beam)

The above is the reinforcement schemes that are often used. In practice, we must choose a reasonable reinforcement scheme according to the site situation. If you have any doubts, please feel free to contact us~:400-894- 5118

Link to this article: https://www.njmkt.net/Article/cydjgjgffy.html

(Editor: Nanjing Mankate, if you need to reprint, please indicate the source)