After seeing the new version of "Heavenly Sword Dragon Slaying Saber”, many audiences and friends may think it is OK at first. It is narrowly like martial arts TV series. After a few weeks, they may complain a lot. There are too many slow-motion shots. So the director came out and explained that in fact, in order to make you see more clearly, the new upgraded shooting technology was applied. However, the ten-minute play, which the netizens can be confused after watching, and the martial arts are almost all slow motions. It seems that netizens can not accept this new technology. As a result of this kind of research that is not good enough to solve problems, housing reinforcement is also prone to security risks.

1. The stress characteristics of the seismic strengthening structure are different from the new structure. The structural reinforcement structure belongs to the secondary force structure and the recombination structure. There are problems of stress and strain lag between the old and the new parts. The structural seismic capacity is insufficient before the reinforcement. The stress level of the section is quite high. When the original structure has been stressed after unloading, the second load is applied, and the newly added part is just beginning to be stressed. Therefore, the section stress and strain value of the original structure are always higher than the stress and strain values of the newly added part. When the original structural part has exceeded the section bearing capacity, the carrying capacity of the newly added part has not yet fully played out.

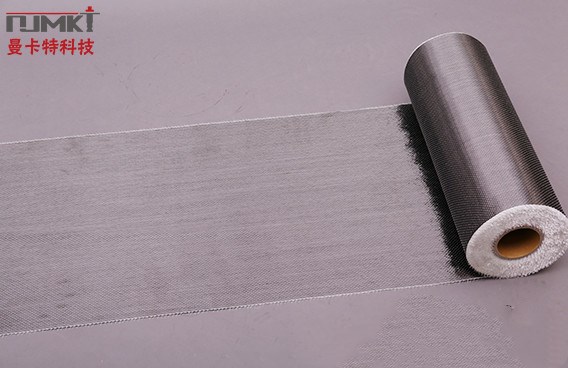

When the newly added part and the original structure work as a whole, the joint surface is particularly complicated, and the shear failure is easy to occur. Therefore, whether the two parts are strongly stressed depends on the joint surface. Considering the above two factors in the seismic reinforcement, it is objectively present, and the impact is considered by using the reduction factor of 0.85. Correlated tests have found that the effect of unloading on the bearing capacity of the reinforced structure is greatly related to the stress and strain level of the original structure during reinforcement. The lower the stress and strain level of the original structure, the more the bearing capacity of the reinforced part can be exerted. Therefore, the original structure should be unloaded before reinforcement. The carbon fiber cloth produced by Nanjing Mankate can be combined with the matching Mankate carbon fiber glue to form a strong and complete carbon fiber cloth reinforcement system. It can withstand low temperature and can be applied at minus 5 degrees. With a long warranty of 50 years, it has a relatively high tensile strength and a strength of 4424 MPa. And the carbon fiber cloth itself is light in weight and does not deepen the weight of the members.

2. Follow the structural seismic design principles. The reinforcement of reinforced concrete frame structure should be based on increasing the overall seismic performance of the building, avoiding the bearing capacity and uneven distribution of the stiffness after reinforcement, and following the basics of “strong column weak beam, strong shear weak bend, strong joint, strong anchoring”. The principle is to ensure that the structure after structural reinforcement has good ductility, and has a large internal force redistribution and the ability to dissipate seismic energy under earthquake action.

The carbon fiber cloth produced by Nanjing Mankate is made of imported Toray carbon wire, which has high flatness and no cutting. It has the advantages of flexible winding forming, light weight, no increase in component weight, and no change in the cross-sectional dimensions of the components. If you are interested in this product, please call our one-stop service hotline: 400-894-5118.

Link to this article: https://www.njmkt.net/Article/xbyttljcpb.html

(Editor: Nanjing Mankate, if you need to reprint, please indicate the source)