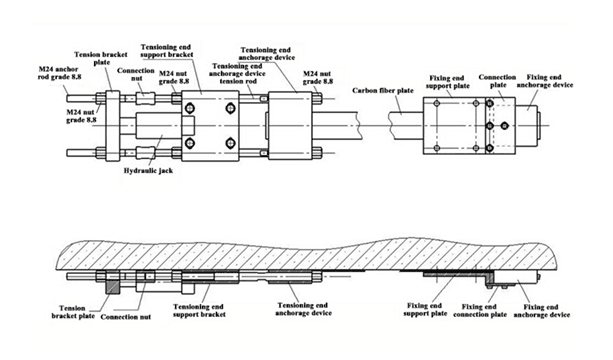

The prestressed carbon fiber board reinforcement method is an emerging structural reinforcement technology in recent years. It combines the advantages of the ordinary bonded carbon fiber board reinforcement method and the prestressed reinforcement method, and is applied to the reinforcement members by prestressing the carbon fiber board. The pulling surface is combined with the reinforcing structural member to increase the bearing capacity of the structure, reduce the deformation of the structure, improve the rigidity of the member, and improve the mechanical performance of the members. Because carbon fiber board has the advantages of light weight, high corrosion resistance, convenient construction and durability, it has great advantages compared with other traditional reinforcement methods (such as steel strand prestress). There is a good development prospect in the field of civil engineering, especially for bridge reinforcement.

Determination of limit state of prestressed carbon fiber sheet reinforcement method

According to the existing research, the failure modes of reinforced concrete beams strengthened with prestressed carbon fiber sheets are mainly as follows:

1. The carbon fiber board and the concrete beam are peeled off before the normal section bending capacity is reached. This type of failure mode is sudden, brittle failure, and the component has poor time-delay. It can be avoided in the project by strengthening the anchoring measures of the carbon fiber board end and ensuring the effectiveness of the bond.

2. The steel bar has not yet yielded. The carbon fiber board has not been broken, and the concrete in the compression zone is crushed and destroyed.

The failure mode is to arrange more steel bars in the beam, so that the steel bars are crushed without yielding the concrete. In this case, it is not suitable to use the pre-stressed carbon fiber board to strengthen the tension zone. It is recommended to adopt other reinforcement methods to improve the bearing capacity.

3. The concrete is not crushed, and the carbon fiber sheet reaches the ultimate tensile stress and break after the steel is yielded.

The failure mode is controlled by the breaking of the carbon fiber board. The bending failure caused by the tensile stress of the prestressed carbon fiber sheet occurs when the reinforcing beam has a small reinforcement ratio and the fiber ratio is small, the ductility is relatively low, and the carbon fiber board is broken.This will give people a feeling of insecurity.

4. The carbon fiber board does not reach the ultimate tensile stress, and the concrete is crushed and destroyed after the steel is yielded. The fourth kind is the same as the third one: the deformation form is more obvious after the yielding of the steel bar, and there is a clear sign before the damage, which is plastic damage. However, the third type of failure is controlled by the breaking of the carbon fiber board. The bending failure caused by the tensile stress of the prestressed carbon fiber sheet occurs when the reinforcing beam has a small reinforcement ratio and the fiber ratio is also small, the ductility is relatively low, and the carbon fiber board is pulled. Broken will give people a feeling of insecurity. Therefore, in the flexural load-bearing reinforcement design, the fourth failure mode, that is, the carbon fiber sheet is not broken, and the concrete crushing capacity limit state should be designed as one of the reinforcement design goals.

Application advantages of prestressed carbon fiber sheet reinforcement

As a new high-strength material, carbon fiber board can be anchored to the surface of concrete structure before being pre-tensioned to a certain design stress before being bonded, which can effectively improve the bending strength and rigidity compared with the non-prestressed carbon fiber board reinforcement method. At the same time, the prestressing technology can reduce the amount of carbon fiber board and save the total cost of the project. Therefore, the prestressed carbon fiber reinforced concrete structure has obvious economic advantages over the ordinary carbon fiber board method.

Good materials make high-quality engineering. It’s important for pre-stressed carbon fiber sheet reinforcement method to match the entire system and all materials should be from one manufacturer. At present, in the market the quality of individual products is almost the same, especially carbon fiber board. Because it depends on carbon fiber filament quality, almost everyone does not produce the carbon fiber filament by themselves. They rely on the importing. Therefore, the anchor system is of utmost importance. If you want to choose carbon fiber board anti-tensioned and prestressed anchors, just choose Mankate big belly anti- wearing anchors. Mankate's second-generation carbon fiber sheet anti-tensioned prestressed anchors, China's famous products, underwritten by Ping An Insurance, corrugated toothed, wedge-shaped self-locking clamping. It has been widely used in Chongqing Yuzhong District overpass, Gongzhuling Bridge reinforcement, Luosanling Expressway Lingbao section highway bridge widening and other projects. If you also have the need for prestressed carbon fiber sheet reinforcement system, please contact Mankate: info@nj-mkt.com