With the accelerating urbanization process, more and more big cities have risen from the ground. In addition to the traditional mega cities like Beijing, Shanghai and Shenzhen, more and more strong first-tier cities, such as Nanjing and Hangzhou, which are constantly catching up. The construction of the city is inseparable from the dense network of pipes. In the underground integrated pipes of the city, the pre-buried trough of the pipes plays a vital role.

Of course, as everyone knows, these tanks are buried deep underground. The underground is not only wet but also has hidden factors such as dark rivers. Therefore, it is very important to do waterproof work on underground integrated pipe corridors. In this way, the service life of the underground integrated pipe gallery can be well extended, and the cost of rework due to damage can be greatly reduced. Today we will talk about what preparations are needed before doing waterproofing.

The first step is to prepare for the early stage of the technical preparation. This step requires technicians to work with the construction workers together. Before the start of the project, the technicians will organize the on-site construction personnel to be familiar with the drawings, clarify the contents of the project, analyze the characteristics of the project and important links, and check whether the types, specifications and quantities of the various materials of the project, such as the pre-buried tanks, are complete and clear.

This is followed by staff scheduling. The person in charge of the construction site and the person in charge of the technology should make a comprehensive consideration, carefully study the manpower required for each construction stage, and do so in order to reduce blindness and avoid the shortage or waste of manpower. At the same time, in the final stage of the project progress, special attention should be paid to the rational arrangement of the process, cross-operation and finished product protection to prevent the completed project from being damaged.

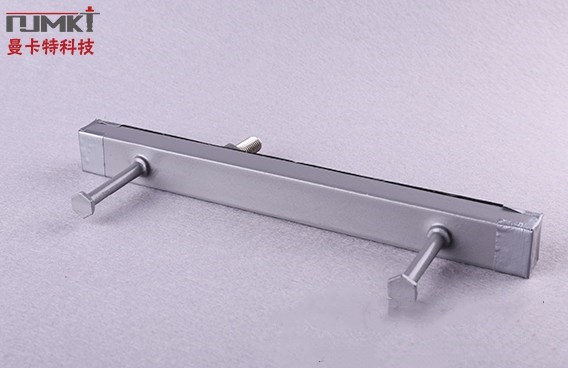

Finally, it is the purchase of construction materials. As the main components of the underground integrated pipes, the quality of the pre-embedded channel also determines the success or failure of the project, such as the mantle pre-buried channel produced by Nanjing Mankate which is made of high-quality steel Q235B, and the surface is carried out with hot-dip galvanized coating ≥ 45um; high anti-corrosion coating ≥ 10um. Such a high quality pipe gallery pre-buried channel can pass the 3000 hour salt spray test without rusting.

Link to this article: https://www.njmkt.net/Mobile/MArticles/csdxzhglym.html

(Editor: Nanjing Mankate, if you need to reprint, please indicate the source)