Recently, we find that there are many changes in the way customers do bridge reinforcement. Old customers who have previously purchased carbon fiber cloth for bridge reinforcement will consider using pre-stressed carbon fiber sheets for bridge reinforcement when purchasing again. Why are there more and more customers choosing pre-stressed carbon fiber sheets? How is the effect?

When it comes to bridge reinforcement, the current commonly used structural reinforcement methods are: carbon fiber reinforcement, carbon steel reinforcement, prestressed reinforcement.

Both carbon fiber reinforcement and bonded steel reinforcement are passive reinforcement. The reinforcement materials start to stress after the reinforcement is completed. Therefore, the stress and strain lag behind the reinforcement structure from the beginning to the end, so that when the reinforcement structure reaches the failure state, the reinforcement materials start to exert force or force is small.

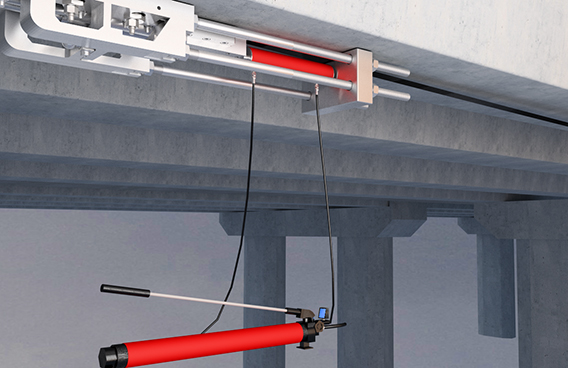

The prestressed carbon fiber board is an active reinforcement technology. It makes full use of high-strength carbon fiber composite materials to avoid premature peeling of carbon fibers, effectively reducing the width of structural cracks and limiting the formation of cracks. At the same time, it has the advantages of “bonded” and “unbonded” prestressing technology. Its tensioning and anchoring system have good mechanical properties, which makes the carbon fiber board evenly stressed, improving the bending stiffness, bearing capacity of the structure and reducing the structural deformation. Among them, the prestressed anchor is a supporting anchor for the prestressed carbon plate reinforcement system, which is often used in bridge construction.

Nanjing Mankate’s prestressed carbon fiber sheet reinforcement system has achieved new breakthroughs and can be used to disassemble anchors. The emergence of detachable anchors makes the anchors reusable, resulting in a significant reduction in anchor costs. At the same time, after the detachable anchor is stretched, under normal circumstances, the anchor can be disassembled and reinstalled only after one day, and because of its miniaturization of the mold, high installation and construction efficiency, and convenient operation, etc. many customers favor it. Let's take a look at the video of the reverse tension construction process of Mankate prestressed carbon fiber sheets.

The three advantages of Mankate prestressed carbon fiber board detachable anchors:

1. Strong construction flexibility (can reasonably arrange construction personnel), high operability and good construction experience.

2. Compared with non-removable anchors, the detachable anchors will not bring too much additional load to the structure (after the tension is completed, the mechanical tool will be removed to hold two pieces of flat anchors on the reinforced paper).

3, Saving resources (the anchors are made of metal), the anchors are highly efficient in recycling, reducing the unnecessary expenses incurred by the anchors for the project.

Prestressed carbon fiber sheet reinforcement technology is an effective method for bending reinforcement of large-span structural panels and for controlling crack reinforcement. Because of its expensive construction cost, some reinforcement projects are prohibitive. Those experienced people know that the expensive cost of pre-stressed carbon fiber sheets is related to anchoring efficiency and the cost of anchoring in engineering cannot be underestimated. Mankate’s detachable prestressed anchors largely solve these problems.

In addition, the prestressed carbon fiber board detachable anchor is suitable for projects with low initial stress requirements. Generally, the tensile strength of carbon fiber sheets can reach 1000 MPa or more. For projects with high initial stress requirements, using fixed anchors to construct is better.

Editor: Nanjing Mankate, if you need to reprint, please indicate the source!

Original link: https://www.njmkt.net/Article/jspmktyylt.html