The post-expansion mechanical anchor bolts commonly used in structural reinforcement are often unclear by many designers and construction workers. There are also some manufacturers who will drill the loopholes of the national standard so that there is great risk in the process of choosing rear expansion mechanical anchors. We hope that this article can help everyone.

So, what is the rear expansion mechanical anchor? How to classify the rear expansion mechanical anchors?

The rear-expanded mechanical anchor is a general term for mechanical anchors that can be used in the load-bearing structure of the seismic fortification zone. The post-expansion mechanical anchor bolts include self-expanding anchor bolts, mold-expanding anchor bolts and adhesive mold-expanding anchor bolts. The classification of these three anchors depends mainly on the way they are installed.

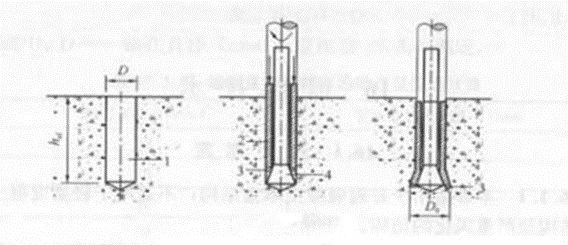

1. Self-expanding anchor

The self-expanding anchor bolt should first drill a straight hole, and then put the anchor bolt into the hole, and the hammer is hit by the mounting rod on the electric hammer combined with the card slot on the anchor expansion sleeve. The anchor is passed under constant hammering rotation. The column cone at the bottom of the bolt causes the lower bottoming head (which must be inlaid with diamond or tungsten carbide) to be cut with coagulation to cut a tapered step to form a locking effect. The basis for judging such anchors is whether the anchor itself has a diamond or tungsten carbide blade, because the hardness of the concrete itself is greater than that of carbon steel. This kind of anchor with the same specification has larger shearing value (with large sleeve). The drilling diameter of the same specification is large and expensive. It has the common problems of mechanical anchor bolts - easy to relax and poor corrosion resistance. It is not recommended to be used in the areas with dynamic loads or corrosive environments.

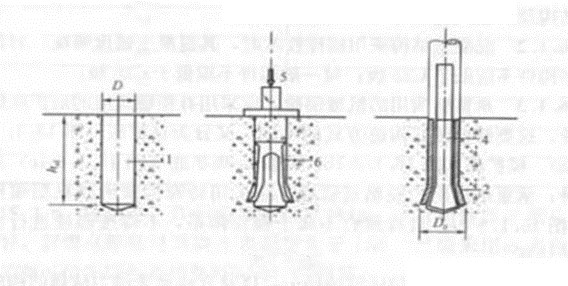

2, mold expansion anchor

When the mold-expanding anchor is installed, it is necessary to drill a straight hole first (note that the following is the difference from the self-expanding anchor). Then use the special mold-expanding tool to expand holes as pushing the pressure in a straight forward way(from the vertical base of the orifice) After reaming. After reaming, the anchor bolt is placed in the bottom hole, and the torque is added to expand the expansion of the bottom of the anchor bolt to form a lock-lock effect with the step at the bottom of the previous reaming. The basis for judging such anchors is mainly to see if a special reaming tool is used to ream the hole in a straight line by pressure. The price of such anchors is low, mainly depends on the cost of the reaming tools, and has the common problems of mechanical anchors - easy to relax, poor corrosion resistance, and is not recommended for using in the areas with dynamic loads or corrosive environments.

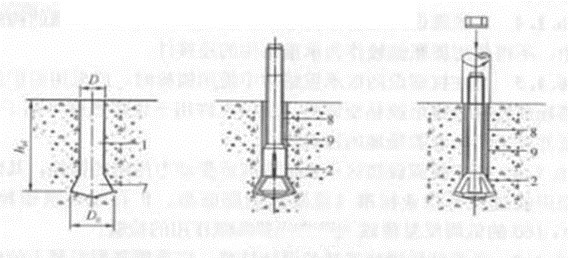

3, adhesive mold expansion anchor bolts

Adhesive mold expansion anchors is first a mold expansion anchor, and the addition of adhesive on the basis of the mold expansion anchor becomes glue mold expansion anchor. Only after reaming, a part of the adhesive is punched into the hole, and then the installation process of the mold bottom anchor is completed. The basis of the anchor is basically the same as that of the mold-expanding anchor, but it is more important to see the quality of the adhesive. The moderate price of such anchors mainly depends on the cost of the reaming tools, and eliminates the common problems of mechanical anchors - easy relaxation and corrosion problems. It can be used in almost any area under the premise of meeting the design bearing capacity.

Editor: Nanjing Mankate, if you need to reprint, please indicate the source!

Original link: https://www.njmkt.net/Article/twxjhkdmsd.html