What is a self-cutting mechanical anchor?

The self-cutting mechanical anchor bolt, as its name suggests, is the anchor bolt that cuts into the concrete itself. The advantage of this anchor bolt is that it does not need to anchor the adhesive. After the mechanical installation of the anchor bolt, it can be used for subsequent operations such as welding, which solves many cases of the disadvantage that the chemical planting bar cannot withstand high temperatures.

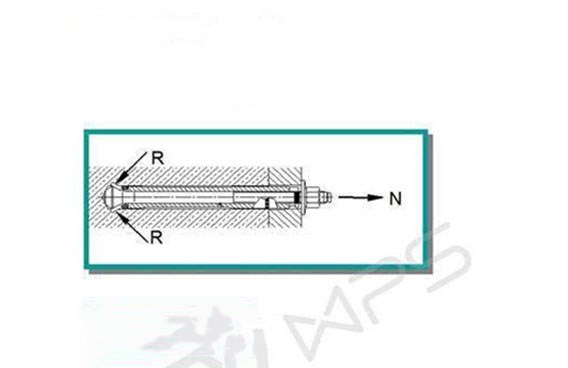

Through the working principle diagram of the self-cutting mechanical anchor bolt, it can be seen that the self-cutting lock key behind the self-cutting mechanical anchor bolt will be opened and cut into the concrete through the self-carrying cutter head, thereby achieving the anchor anchor effect.

After the self-cutting mechanical anchor is installed into the concrete:

Through the cross-section of the concrete cut by the self-cutting mechanical anchor bolt that we cut with the cutter, we can see that there are many inferior anchor bolts, which are only similar in shape to the self-cutting mechanical anchor bolt, but the lock key is difficult to open, thus forming the effect of the expansion anchor, but the principle of the self-cutting mechanical anchor and the expansion anchor is completely different.

What is the difference between self-cutting mechanical anchors and expansion anchors?

The above figure shows the force of the concrete when the various anchor bolts are stressed. It can be seen that the force of the self-cutting mechanical anchor and the large-headed embedded part is almost the same, which is the best form of the anchor. The stress zone of the expansion anchor is too large, which results in a larger spacing and margin and a deeper anchoring depth for the expandable anchor.

What are the characteristics of self-cutting mechanical anchors?

1. It has a good carrying capacity.

2. It has the function of cutting into the substrate by itself under the action of torsion.

3. There is almost no expansion stress in the natural environment to meet different buried depth requirements.

4. It is suitable for a variety of angles including the head of the face fixed, suitable for small margins and small spacing installation.

5. Professional, scientific and rigorous design ensures effective and safe tensile strength and shear resistance.

What grades of self-cutting mechanical anchors should I choose?

In the representation methods of anchor bolts, words such as 5.8 and 8.8 can often be heard. So what do these grades mean?

According to the stipulations of GB/T3098.1-2000, the performance grades of anchor bolts are divided into 4.8, 5.8, 6.8, 8.8, 10.9, and 12.9, and the commonly used grades are 5.8 and 8.8. So what do these levels mean? And how do we choose?

The 6.8 grade indicates that the standard value of tensile strength is 600 MPa and the standard value of yield strength is 480 MPa. Because its elongation does not meet the 8% standard of the steel structure design specification, and it is not recommended.

High-strength bolts of 10.9 and 12.9 are generally not recommended because the high-strength bolts have high hardness after heat treatment, and the surface anti-corrosion treatment in the later stage increases the probability of hydrogen embrittlement.

Grade 8.8 indicates that the standard value of tensile strength is 800 MPa and the standard value of yield strength is 640 MPa. This strength has the highest bolt usage and the highest price/performance ratio.

Editor: Nanjing Mankate, if you need to reprint, please indicate the source!

Original link: https://www.njmkt.net/Article/zqdmsgzwtx.html