● Material: alloy steel grade 5.8, 6.8, 8.8, 10.9, 12.9; stainless steel 50 70 80

● Designed high strength chemical anchor, suitable for all kinds of concrete base material, even cracked concrete

● The main components of the chemical cartridge are modified epoxy resin, grade A adhesive; high/low temperature resistance and aging-resistance

● Injection embeddment, without disadvantage of uneven mixing

● We also provide specialized underwater adhesive for damp and water-filled holes for effective anchorage

● We recommend our excellent NJMKT Anchorage Adhesive (MT-500 cartridge or barrel) for NJMKT adhesive anchors

Characteristics

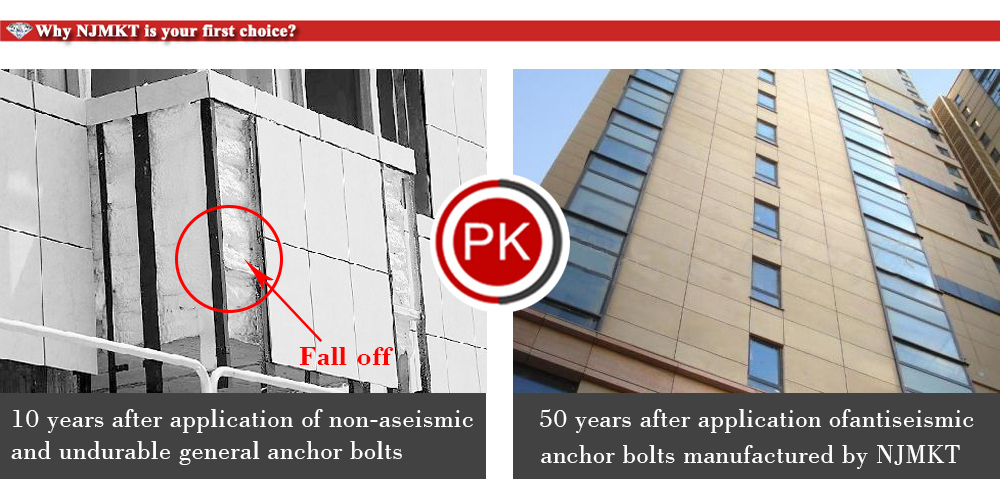

● Excellent comprehensive performance, safe and reliable, construction tolerance is higher than conventional chemical anchor, non-toxic environmental protection, aging-resistance up to 50 years and high/low temperature resistance

● Comparing with mechanical anchors, the same tensile strength characteristics but low price advantage for your choice

● steel structure

● bridge and tunnel

● industrial plant

● building curtain wall

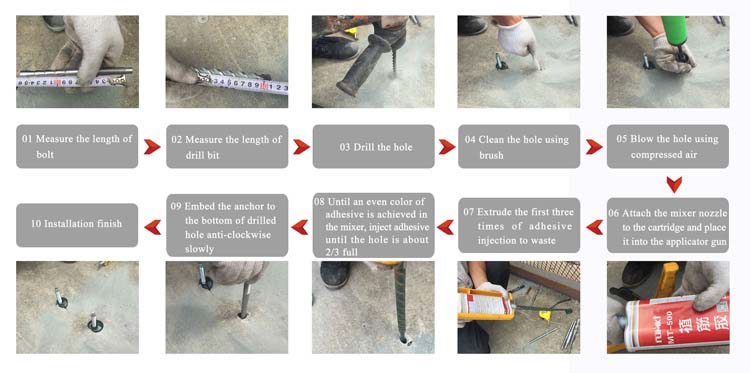

Installation flow chart

1.Measure the length of bolt

2.Measure the length of drill bit

3.Drill the hole

4.Clean the hole using brush

5.Blow the hole using compressed air

6.Attach the mixer nozzle to the cartridge and place it into the applicator gun

7.Extrude the first three times of adhesive injection to waste

8.Until an even color of adhesive is achieved in the mixer, inject adhesive until the hole is about 2/3 full

9.Embed the anchor to the bottom of drilled hole anti-clockwise slowly

10.Installation finish

Installation Guide

● Drill the hole to proper depth and diameter per specifications using drill systems.

● Clean the hole using brush and compressed air.

● Use specialized cartridge, place the cartridge into the dispensing tool, discard the first several times of injection until an even-colored mixture is extruded.

● Insert the mixing nozzle to the bottom of the hole, and inject adhesive until the hole is about 2/3 full.

● Embed the steel anchor element to the bottom of drilled hole clockwise slowly.

● Check the surface of the hole if there is any overflow to ensure the hole is full. There shall be no gaps between the anchor and the wall of the drilled hole. Clean any excess resin from around the mouth of the hole.

●Do not knock or strike the steel during cure time.

● Finish installation and continue the follow-up construction.

| Size | Drilled hole depth (mm) | Drilled hole dia. (mm) | Rod length(mm) | Max. Fixture thickness (mm) |

| M12 | 110 | 14 | 160 | 28 |

| M16 | 125 | 18 | 190 | 38 |

| M20 | 170 | 24 | 260 | 48 |

| M24 | 210 | 28 | 300 | 54 |

| Basic design specifications (steel grade 8.8) | ||||

| Size | M12 | M16 | M20 | M24 |

| anchorage depth (mm) | 110 | 125 | 170 | 210 |

| tension failure average value (kN) (00) | 67.4 | 125.6 | 196 | 282 |

| shear failure average value (kN) (900) | 40.4 | 75.3 | 117.6 | 169.2 |

| Design tension load (kN) (00) | 51.8 | 96.6 | 150.7 | 217 |

| Design shear load (kN) (900) | 31 | 58 | 90.4 | 130.1 |

| Basic design specifications (steel grade 5.8) | ||||

| Size | M12 | M16 | M20 | M24 |

| anchorage depth (mm) | 110 | 125 | 170 | 210 |

| tension failure average value (kN) (00) | 42.2 | 78.5 | 122.5 | 176.4 |

| shear failure average value (kN) (900) | 25.3 | 47.1 | 73.5 | 105.8 |

| Design tension load (kN) (00) | 28.1 | 52.3 | 81.7 | 117.6 |

| Design shear load (kN) (900) | 15.2 | 28.3 | 44.1 | 58.1 |

● The values are suitable for: correct installation, no influence of spacing and edge distance, minimum base material thickness.

● All the data applies in C20/25 concrete base material. If the base material grade changes, the corresponding concrete influence coefficient will needs to be increased.

● The * part in the table is steel failure control.

● The material of all the anchors in the table is alloy steel, grade 8.8.

● Design load: including material partial factor, but not including overall partial factor.

● Recommended load: including not only material partial factor, but also including overall partial factor 1.4.

● If your anchor with special material and specification is not listed in this table, please contact our engineer for advice.

● All basic anchor data in this table is given according to 2013 ETAG001 and Appendix. The partial factor in the load application must be in accordance with national regulation