Key Features

● Consist: anchor rod, undercut lock, spacer sleeve, flat washer, anti-seismic washer, nut

● Material:carbon steel, alloy steel, stainless steel

● Anti-corrosive treatment:

galvanized steel≥5μm, applicable in indoor and outdoor surroundings

hot-dip galvanized steel≥45μm, applicable in corrosion environment

● Customers can accept engineer’s suggestions: applicable in long-lasting complex environment with NJMKT special surface treatment high-performance anti-corrosion thickness ≥10μm

Advantages

● Lock-effect anchor fixing

● Convenient installation, consistent and reliable performance, torque-turn for load-carrying-----bearing capability

● No waste holes, completely detachable for repeated use

● The anchor holes can be reused if concrete base material is not damaged

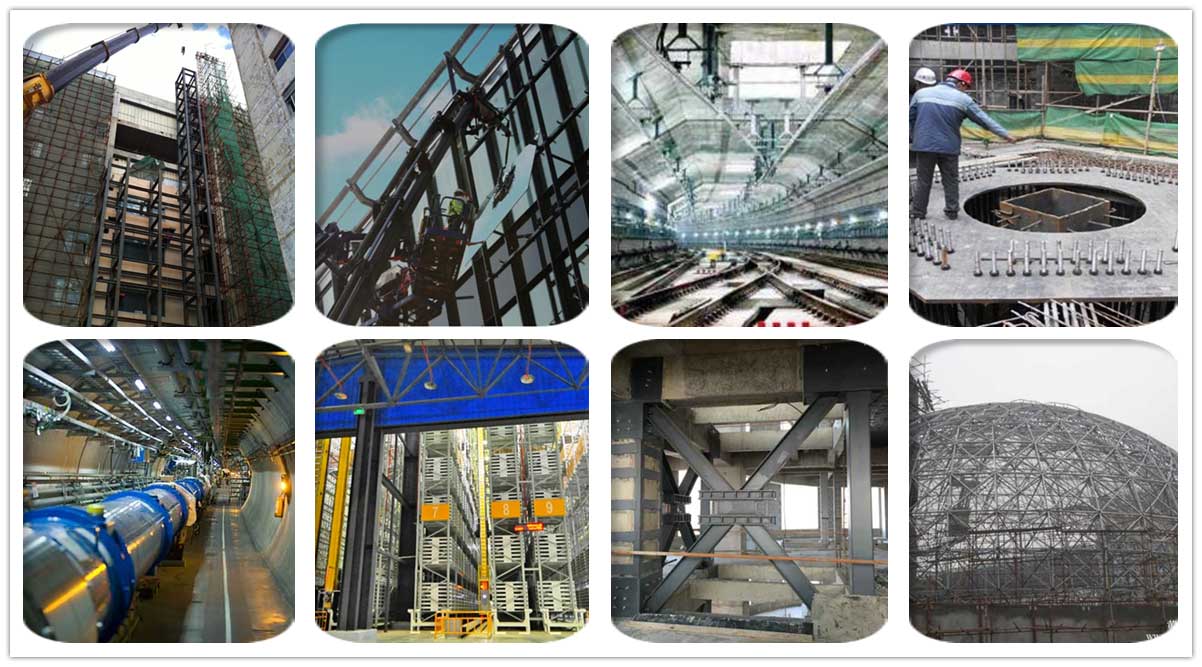

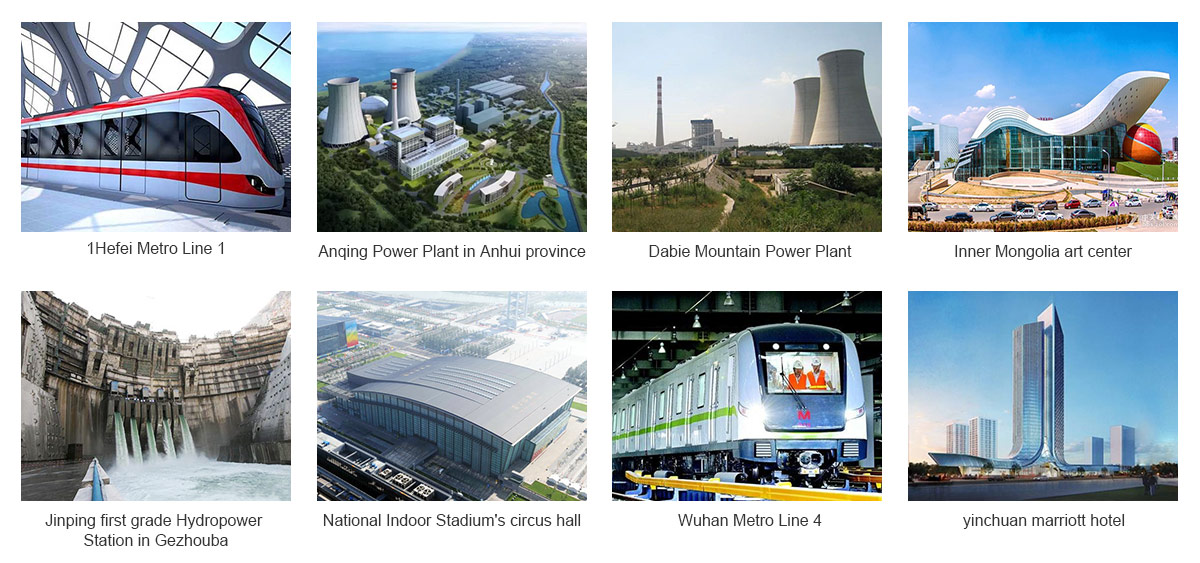

● Especially suitable for complex environment such as petrochemical industry base, ports, subways, etc.

● Lock-effect anchor fixing

● Convenient installation, consistent and reliable performance, torque-turn for load-carrying-----bearing capability

● No waste holes, completely detachable for repeated use

● The anchor holes can be reused if concrete base material is not damaged

● Especially suitable for complex environment such as petrochemical industry base, ports, subways, etc.

● Lock-effect anchor fixing

● Convenient installation, consistent and reliable performance, torque-turn for load-carrying-----bearing capability

● No waste holes, completely detachable for repeated use

● The anchor holes can be reused if concrete base material is not damaged

● Especially suitable for complex environment such as petrochemical industry base, ports, subways, etc.

| The average failure load, design load, and recommended load of a single anchor in large spacing and edge distance | |||||||||

| Pre-Set type C20/25 concrete base material | |||||||||

| uncracked concrete | |||||||||

| Size | M10/16 ×60 | M12/18 ×100 | M12/18 ×120 | M16/22 ×130 | M16/28 ×160 | M16/28 ×200 | M20/35 ×210 | M20/35 ×250 | M24/38 ×285 |

Effective embedment depth hef [mm] | 60 | 100 | 120 | 130 | 160 | 200 | 210 | 250 | 285 |

Drilled hole depth ho [mm] | 75 | 115 | 135 | 145 | 175 | 215 | 225 | 265 | 300 |

Drilled hole dia. do [mm] | 16 | 18 | 18 | 22 | 28 | 28 | 35 | 35 | 38 |

| Average failure load | |||||||||

Tensile force 0°[kN] Nu | 31.4 | 67.4* | 67.4* | 100 | 125.6* | 125.6* | 196* | 196* | 282* |

Shear force 90°[kN] Vu | 27.8* | 40.4* | 40.4* | 75.4* | 75.4* | 75.4* | 117.6* | 117.6* | 169.2* |

Design load | |||||||||

Tensile force 0°[kN] NRd | 14.5 | 44.9 | 44.9 | 46.3 | 83.7 | 83.7 | 130.7 | 130.7 | 188 |

Shear force 90°[kN] VRd | 18.5 | 26.9 | 26.9 | 50.2 | 50.2 | 50.2 | 78.4 | 78.4 | 112.8 |

recommended load | |||||||||

Tensile force 0°[kN] Nu | 10.4 | 32.1 | 32.1 | 22.1 | 59.8 | 59.8 | 93.4 | 93.4 | 134.2 |

Shear force 90°[kN] Vu | 13.2 | 19.2 | 19.2 | 35.9 | 35.9 | 35.9 | 56 | 56 | 80.6 |

Base material size, minimum spacing and edge distance | |||||||||

Min.spacing smin [mm] | 60 | 100 | 100 | 130 | 160 | 160 | 250 | 250 | 285 |

Min.edge distance cmin [mm] | 60 | 100 | 100 | 130 | 160 | 160 | 250 | 250 | 285 |

Min. base material thickness hmin [mm] | 120 | 200 | 200 | 260 | 320 | 320 | 500 | 500 | 570 |

Installation torque tinst [mm] | 40 | 60 | 60 | 100 | 140 | 140 | 300 | 300 | 500 |

| The average failure load, design load, and recommended load of a single anchor in large spacing and edge distance | |||||||||

| Pre-Set type C20/25 concrete base material | |||||||||

| cracked concrete | |||||||||

| Size | M10/16 ×60 | M12/18 ×100 | M12/18 ×120 | M16/22 ×130 | M16/28 ×160 | M16/28 ×200 | M20/35 ×210 | M20/35 ×250 | M24/38 ×285 |

Effective embedment depth hef [mm] | 60 | 100 | 120 | 130 | 160 | 200 | 210 | 250 | 285 |

Drilled hole depth ho [mm] | 75 | 115 | 135 | 145 | 175 | 215 | 225 | 265 | 300 |

Drilled hole dia. do [mm] | 16 | 18 | 18 | 22 | 28 | 28 | 35 | 35 | 38 |

| Average failure load | |||||||||

Tensile force 0°[kN] Nu | 22.1 | 47.5 | 62.4 | 70.4 | 96.1 | 125.6* | 144.6 | 187.7 | 228.5 |

Shear force 90°[kN] Vu | 27.8* | 40.4* | 40.4* | 75.4* | 75.4* | 75.4* | 117.6* | 117.6* | 169.2* |

| Design load | |||||||||

Tensile force 0°[kN] NRd | 10.2 | 22 | 28.9 | 32.6 | 44.5 | 83.7 | 66.9 | 86.9 | 105.8 |

Shear force 90°[kN] VRd | 18.5 | 26.9 | 26.9 | 50.2 | 50.2 | 50.2 | 78.4 | 78.4 | 112.8 |

| recommended load | |||||||||

Tensile force 0°[kN] Nu | 7.3 | 15.7 | 20.6 | 23.3 | 31.8 | 59.8 | 47.8 | 62.1 | 75.6 |

Shear force 90°[kN] Vu | 13.2 | 19.2 | 19.2 | 35.9 | 35.9 | 35.9 | 56 | 56 | 80.6 |

| Base material size, minimum spacing and edge distance | |||||||||

Min.spacing smin [mm] | 60 | 100 | 100 | 130 | 160 | 160 | 250 | 250 | 285 |

Min.edge distance cmin [mm] | 60 | 100 | 100 | 130 | 160 | 160 | 250 | 250 | 285 |

Min. base material thickness hmin [mm] | 120 | 200 | 200 | 260 | 320 | 320 | 500 | 500 | 570 |

Installation torque tinst [mm] | 40 | 60 | 60 | 100 | 140 | 140 | 300 | 300 | 500 |

● The values are suitable for: correct installation, no influence of spacing and edge distance, minimum base material thickness.

● All the data applies in C20/25 concrete base material. If the base material grade changes, the corresponding concrete influence coefficient will needs to be increased.

● The * part in the table is steel failure control.

● The material of all the anchors in the table is alloy steel, grade 8.8.

● Design load: including material partial factor, but not including overall partial factor.

● Recommended load: including not only material partial factor, but also including overall partial factor 1.4.

● If your NJMKT Dismountable Anchor(Mechanical Anchors) with special material and specification is not listed in this table, please contact our engineer for advice.

● All basic anchor data in this table is given according to 2013 ETAG001 and Appendix. The partial factor in the load application must be in accordance with national regulation.