Feature:

* Anti-aging and anti-medium (acid, alkali, water)

* Excellent toughness and good impact resistance after cured, high tensile strength of 27Mpa

* High permeability, even for 0.1mm crevice

* Very good resistance to age, medium( acid, alkali and water)

* No volatile solvent, nearly no shrink during cure

* Safe and non-toxic, easy construction process

* Transparent and colorless, no irritating smell, environmental non-toxic

* Its strength is higher than the concrete, and the degree of fusion with the concrete is perfect, aging resistance is for more than 50 years

* Suitable for crack repair in concrete project

* Widely used for concrete interior defects (honeycomb, porosity ) injection repair

* Hollowing wall and floor tile filling

Installation:

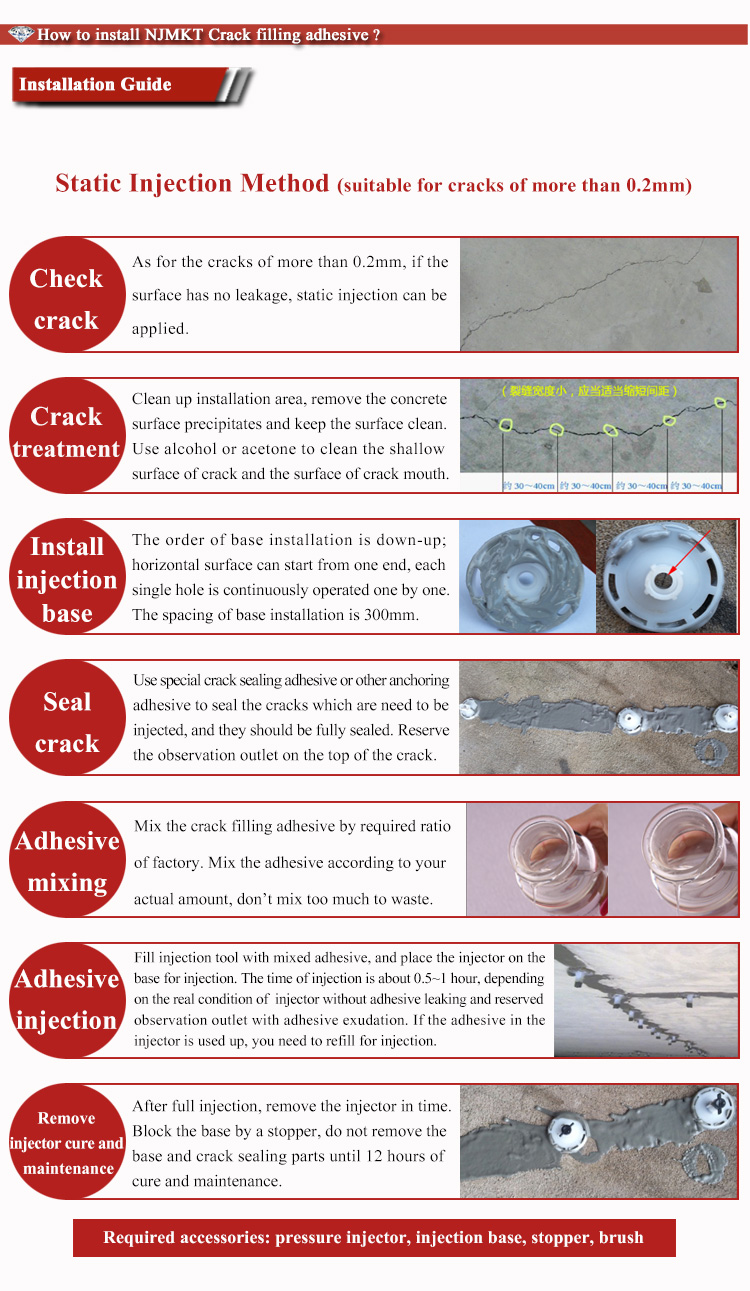

A: Static Injection Method (suitable for cracks of more than 0.2mm)

1. Crack checking: As for the cracks of more than 0.2mm, if the surface has no leakage, static injection can be applied.

2. Crack treatment: Clean up installation area, remove the concrete surface precipitates and keep the surface clean. Use alcohol or acetone to clean the shallow surface of crack and the surface of crack mouth.

3. Injection base installation: The order of base installation is down-up; horizontal surface can start from one end, each single hole is continuously operated one by one. The spacing of base installation is 300mm.

4. Crack sealing: Use special crack sealing adhesive or other anchoring adhesive to seal the cracks which are need to be injected, and they should be fully sealed. Reserve the observation outlet on the top of the crack.

5. Sealing checking: Check the sealed cracks to ensure there is no air leakage.

6. Adhesive mixing: Mix the crack filling adhesive by required ratio of factory. Mix the adhesive according to your actual amount, don’t mix too much to waste.

7. Adhesive injection: Fill injection tool with mixed adhesive, and place the injector on the base for injection. The time of injection is about 0.5~1 hour, depending on the real condition of injector without adhesive leaking and reserved observation outlet with adhesive exudation. If the adhesive in the injector is used up, you need to refill for injection.

8. Remove the injector, curing and maintenance: After full injection, remove the injector in time. Block the base by a stopper, do not remove the base and crack sealing parts until 12 hours of cure and maintenance.

Required accessories: pressure injector, injection base, stopper, brush

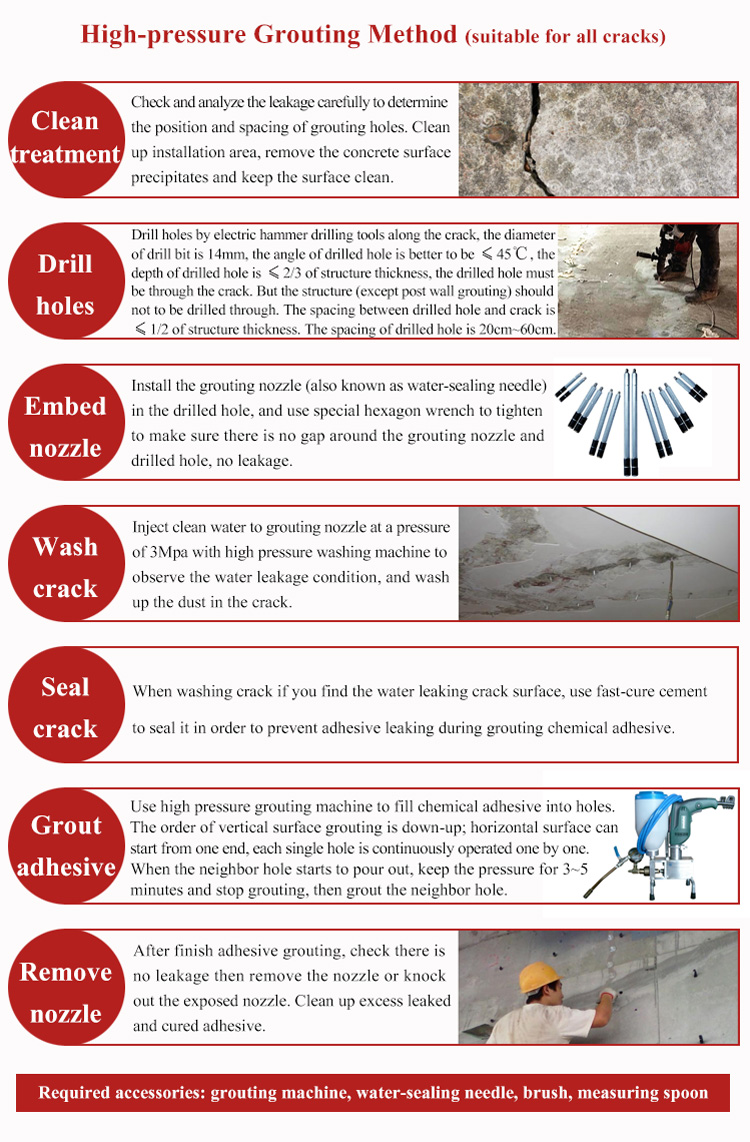

B:High-pressure Grouting Method (suitable for all cracks)

1. Clean treatment: Check and analyze the leakage carefully to determine the position and spacing of grouting holes. Clean up installation area, remove the concrete surface precipitates and keep the surface clean.

2. Holes drilling: Drill holes by electric hammer drilling tools along the crack, the diameter of drill bit is 14mm, the angle of drilled hole is better to be ≤45℃, the depth of drilled hole is ≤2/3 of structure thickness, the drilled hole must be through the crack. But the structure (except post wall grouting) should not to be drilled through. The spacing between drilled hole and crack is ≤1/2 of structure thickness. The spacing of drilled hole is 20cm~60cm.

3. Embed the nozzle: Install the grouting nozzle (also known as water-sealing needle) in the drilled hole, and use special hexagon wrench to tighten to make sure there is no gap around the grouting nozzle and drilled hole, no leakage.

4. Crack washing: Inject clean water to grouting nozzle at a pressure of 3Mpa with high pressure washing machine to observe the water leakage condition, and wash up the dust in the crack.

5. Crack sealing: When washing crack if you find the water leaking crack surface, use fast-cure cement to seal it in order to prevent adhesive leaking during grouting chemical adhesive.

6. Adhesive grouting: Use high pressure grouting machine to fill chemical adhesive into holes. The order of vertical surface grouting is down-up; horizontal surface can start from one end, each single hole is continuously operated one by one. When the neighbor hole starts to pour out, keep the pressure for 3~5 minutes and stop grouting, then grout the neighbor hole.

7. Remove the nozzle: After finish adhesive grouting, check there is no leakage then remove the nozzle or knock out the exposed nozzle. Clean up excess leaked and cured adhesive.

8. Sealing treatment: Repair and seal the mouth of crack grouting by fast-cure cement.

Required accessories: grouting machine, water-sealing needle, brush, measuring spoon

Caution:

*Mix the adhesive well according to its weight proportion strictly

*Construction crew should take steps of protective measures to keep it from eyes

*Remaining adhesive cannot be poured into original barrels

Packing:

*Two kinds of package, 30kg (A+B two barrels)/pair; 10kg (A+B two barrels)/pair.

Storage:

*Shelf life: At least 12 months from date of manufacture in unopened container when store in dry and well-ventilated place. Please store in ambient temperature from 5 ℃ to 40 ℃, away from open flame, heating devices

*Adhesive specialized for low temperature can be stored in ambient temperature from -5 ℃ to 40 ℃

*Handle with care, protect from rain, sunlight and place upward during loading and unloading transportation

Standard: GB50367-2013, GB50728-2011

NJMKT promises to meet the technical requirements of the following GB50367-2013 "Design code for concrete structure reinforcement" and GB50728-2011 "Technical code for safety identification of reinforcement materials for engineering structures".

| NO. | Item Name | Technical Specification | Test Result | Single item assessment |

| 1 | Tensile strength (MPa) | ≥ 25 | 27 | Qualified |

| 2 | Tensile modulus of elasticity (MPa) | ≥ 1500 | 1542 | Qualified |

| 3 | Elongation(%) | ≥ 1.7% | 3.99% | Qualified |

| 4 | Bending strength (MPa) | ≥ 30, and without brittle failure | 36, and without brittle failure | Qualified |

| 5 | Compressive strength (MPa) | ≥ 50 | 51 | Qualified |

| 6 | Steel-steel tensile shear strength (MPa) | ≥ 15 | 15.1 | Qualified |

| 7 | Steel-concrete positive tensile bonding strength (MPa) | ≥ 2.5, and concrete cohesive failure | 2.9, and concrete cohesive failure | Qualified |

Cure Time:

| Base material temperature | Gel time | Time of start curing | Time of complete curing |

| -5°C-0°C | 3h | 18h | 240h |

| 0°C-10°C | 2h | 12h | 216h |

| 10°C-20°C | 1&1/3h | 10h | 192h |

| Above 20°C | 1h | 8h | 168h |

Technical Specification

| Adhesive Performance | Viscosity (mp,25℃) | 80 |

| Density (g/cm3,25℃) | 1.0 | |

| Compressive strength (MPa) | 51; (GB/T2569) | |

| Bending strength (MPa) | 35; (GB/T2570) | |

| Tensile strength (MPa) | 23; (GB/T2568) | |

| Bonding Capability | Steel-steel positive tensile bonding strength (MPa) | 18-27; (GB/T6329) |

| Steel-steel shear bonding strength (MPa) | 10-18; (GB/T7124) | |

| 60 times freeze-thaw cycle | Positive tensile bonding strength-No significant change | |

| Aging Resistance Performance | (-35℃--35℃, every 12h as a cycle) | Shear bonding strength-No significant change |

| -35℃-- 60℃, under stable temperature | Shear bonding strength >10Mpa |