Key Features

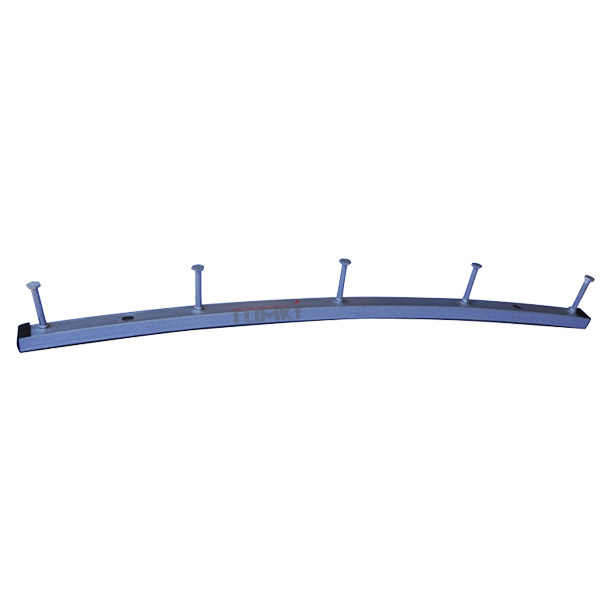

● Material: 235B, 06Cr17Ni12Mo2Ti, or other customized material

● The lateral channel stiffener has key lock effect, when buried in concrete, it can improve the hold strength with the concrete

● Hot dipped galvanized ≥80 μm, excellent corrosion resistance, surface treatment can be required for long-lasting complex environment with NJMKT special process of anti-corrosion treatment

● Equipped with T-shape foam filler to prevent adhesive leakage

● Instead of drilling to install, zero damage to tunnel structure

● It can be installed in concrete tensile and compression area

● Highly anti-corrosive performance carbon steel

● It can not only bear static load, but also dynamic load, and it even can bear the load in case of fire

● Safety installation, dust-free, noiseless, vibration-free

cast in channel systems,cast in channel,anchor channels, t- bolts, T-bolts

● It can be used as the ideal solution of anchorage point load bearing for cast in place and precast concrete members

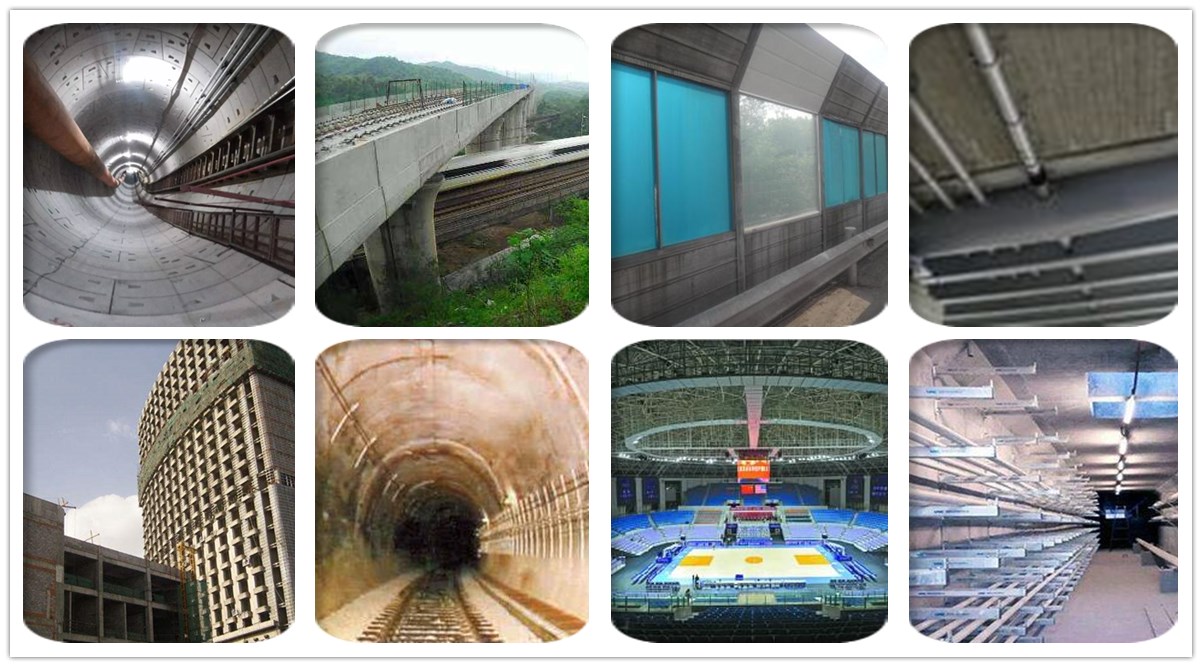

● Railway bridges suspension platform installation

● Railway box beam inner and outer drainage pipe installation

● Railway integrated grounding connection

● Subway tunnel segment channel and equipment fixing and installation

● High-speed railway tunnel servomotor equipment precast installation

● Railway transportation: communication, signal, electric power, overhead contact system, traction substation...the power supply cable sliding channels (embedded groove)

● Curtain wall keel fixing, instead of embedded parts

● All steel-structure project of embedded parts

cast in channel systems,cast in channel,anchor channels, t- bolts, T-bolts

cast in channel systems,cast in channel,anchor channels, t- bolts, T-bolts

Installation

1. Accurate preparation: choose correct model cast-in channels according to design drawings, cut cast-in channels according to different length.

2. Cast-in channels fixing

Choose suitable installation method according to actual working condition.

Take the fixing on the plate as an example:

A. Fix with diamond bolt

B. Fix with nut washer + ordinary bolt

Storage

When store in a room on the ground, put a layer of waterproof film on the ground and two rows of dry wood on the film, place cast-in channels on the wood; separate channels according to different model for ease of use; each bundle of unpacked channels is also need to be placed on the dry wood.

If there is no place in the room and they have to be stored outdoor, the same storage method is as above, but the surface must be covered with a waterproof layer, such as tarpaulin etc. to prevent corrosion because of weather.

The stacking height of channels should be strictly controlled, the maximum height should not be more than 1 meters (3 bundles); mark warning sign and prepare protection measures to prevent them from falling down and avoid the hurts to persons. Forbidden step on the stacking channels.

cast in channel systems,cast in channel,anchor channels, t- bolts, T-bolts

NJMKT Cast-in Channels Specifications----Curtain wall project or equate with curtain wall project

cast in channel systems,cast in channel,anchor channels, t- bolts, T-bolts

| Type | Length | Width | Section height | Effective embedment depth | Rivet dia. | Rivet spacing (S') | Rivet quantity | Rivet edge distance (C') |

| 30/20 | 100~300 | 30 | 20 | 90 | 8 | 50≤S'≤125 | 2 | C'≥25 |

| 30/26 | 100~300 | 30 | 26 | 90 | 8 | 50≤S'≤125 | 2 | C'≥25 |

| 40/30 | 250~330 | 40 | 30 | 100 | 10 | 100≤S'≤140 | 3 | C'≥25 |

| 40/25 | 250~330 | 40 | 25 | 100 | 10 | 100≤S'≤140 | 3 | C'≥25 |

| 50/25 | 250~330 | 50 | 25 | 120 | 12 | 100≤S'≤140 | 3 | C'≥25 |

| 50/30 | 250~330 | 50 | 30 | 120 | 12 | 100≤S'≤140 | 3 | C'≥25 |

| 54/32 | 250~350 | 54 | 32 | 125 | 12 | 100≤S/≤150 | 3 | C'≥25 |